Industry Insights

/

Jun 4, 2025

Cost of Submittal Rejection: The True Financial Impact on Your Projects

Our survey of 6,000+ construction professionals revealed each rejected submittal costs $805—here's how we calculated that number.

Every rejected submittal costs your project $805 on average. When you're processing hundreds or thousands of submittals annually, the cost of submittal rejection quickly becomes one of your biggest hidden budget drains.

For a typical construction project with 2,000 submittals and a 30% rejection rate? That's $483,000 in avoidable costs - money that could have gone straight to your bottom line.

If you're in construction, you know the submittal rejection rate in the industry hovers around 30-40%. What you might not know is the actual dollar amount each rejection costs your project, or how the submittal delay impacts compound across your annual project portfolio.

At BuildSync, we set out to answer one critical question: What does a single rejected submittal actually cost a project?

Why the Cost of Submittal Rejection Matters More Than Ever

Construction margins have never been tighter. According to Associated General Contractors of America, 78% of construction firms experienced at least one project delay in the past twelve months, with workforce shortages and submittal process bottlenecks topping the list of causes.

Meanwhile, Engineering News-Record reports that payment cycles have lengthened by 8-12 days over the past year, tightening cash flow across the board.

In this environment, every dollar matters. And the cost of submittal rejections - both the immediate financial hit and the cascading submittal delays - represents a massive opportunity for recovery.

How We Calculated the $805 Average Cost of Submittal Rejection

To understand submittal rejection costs, we connected with over 6,000 construction professionals and ran comprehensive surveys with more than 200 of them.

We asked about rejection rates, downstream effects, and cost implications across different project types and company sizes.

Our survey included:

General contractors ranging from $50M to $2B+ in annual revenue

Subcontractors across MEP, structural, and finish trades

Operations Managers, project managers, and Project Engineers

Projects spanning commercial, healthcare, education, and industrial sectors

Breaking Down Submittal Rejection Costs by Impact Level

Not all rejections cost the same. Here's what we uncovered:

25% of rejections have minimal impact

These are typically submitted early in the submittal process and may need revisions, but the delay causes no downstream issues. The cost here is mainly administrative time to resubmit - let's call it negligible.

Cost impact: ~$0

65% of rejections cause operational friction

This is where real costs add up. Project managers, Superintendents, Foremen, and Engineers get pulled into conversations to resolve issues. Time is spent:

Reviewing rejection reasons and updating the submittal log

Rescheduling delivery dates and coordinating with the job site

Updating project timelines across the approval process

Managing stakeholder communications

Cost impact: ~$500 per rejection

9% become critical issues

These rejections lead to project delays, field rework, or detailing changes. They require:

Design teams involvement for clarifications on design intent

Additional equipment or labor mobilization

Acceleration costs from schedule compression

Expedited shipping for replacement materials

Cost impact: ~$2,000 per rejection

1% result in significant project delays

The most severe cases can delay substantial completion, trigger delayed occupancy, and potentially result in liquidated damages. These costs include:

Liquidated damages

Cascade effects on subsequent trades

Client relationship impacts

Extended general conditions

Cost impact: ~$30,000 per occurrence

The Math: Weighted Average Cost

Using these averages and their frequency, the weighted average cost per rejected submittal breaks down to:

25% × $0 = $0.00

65% × $500 = $325.00

9% × $2,000 = $180.00

1% × $30,000 = $300.00

Total average cost per rejected submittal: $805.00

How Much Do Submittal Rejections Cost Your Projects Annually?

The average cost of submittal rejection is $805, but what does this mean for your actual projects?

For a company processing 2,000 submittals annually with a 30% rejection rate (which is on the low end in our experience), that equates to:

2,000 submittals × 30% rejection rate × $805 = $483,000 wasted annually on submittal rejections

That's nearly half a million dollars. For a mid-sized general contractor doing $150-200M in annual revenue, this represents 0.2-0.3% of revenue lost to a completely preventable submittal process failure.

Project Size | Annual Submittals | Industry Avg Rejection Rate | Total Annual Rejections | Cost per Rejection | Total Annual Cost | Average PE Hours/Week on Reviews |

Small Contractor ($50-100M) | 500 | 35% | 175 | $805 | $140,875 | 15-20 hours |

Mid-Size Contractor ($100-300M) | 2,000 | 30% | 600 | $805 | $483,000 | 20-30 hours |

Large Contractor ($300-500M) | 5,000 | 30% | 1,500 | $805 | $1,207,500 | 30-40 hours |

Enterprise Contractor ($500M+) | 10,000+ | 28% | 2,800+ | $805 | $2,254,000+ | 40+ hours |

What Is the Submittal Rejection Rate in Construction?

The submittal rejection rate in construction averages 30-40% industry-wide. Our research confirms what most construction professionals already know: roughly one-third of all construction submittals get sent back on first review.

This rejection rate hasn't improved in decades because, until recently, there was no scalable alternative to manual review. Project managers and engineers spend 20+ hours per week reviewing submittals manually - extracting data from 70-page cut sheets, comprehensive shop drawings, and installation instructions, then cross-referencing against dense technical specifications.

The problem isn't competence. It's capacity.

When PEs are drowning in submittal backlog without adequate review time, they miss details. In today's tight labor market, overcoming labor shortages means maximizing the productivity of the PEs you have - not burying them in manual submittal review.

When GCs rush preliminary reviews to keep things moving, non-compliant items slip through. When architects are overwhelmed with submissions, they default to "Revise and Resubmit" for issues that could be "Approved as Noted."

The submittal process is broken. And the cost of submittal rejection proves it. Fortunately, there are proven ways to improve your construction submittal review process that can dramatically reduce these costs.

When asked about the changes in the industry that made the 30-40% rejection rate unacceptable, Luke Paulo, the co-founder of BuildSync, says:

Companies might reach this conclusion for different reasons. Whether they took a massive hit on a project, employee burnout reached a breaking point, or their relationship with an architect is getting too strained.

The Hidden Costs: What the $805 Average Doesn't Capture

Extended General Conditions

When a delayed submittal extends your substantial completion date, you incur Extended General Conditions (EGCs) - the daily, time-related costs of maintaining the project site.

General Conditions typically account for 5-12% of a construction project's total budget. On a $25M project with an 8% GC allowance, that's $2M in General Conditions spread across, say, 18 months (540 days).

Daily EGC rate: $2,000,000 ÷ 540 days = $3,704 per day

When a critical submittal is rejected and the 14-day review clock restarts, the financial impact is immediate:

14 days × $3,704 per day = $51,856

That single "Revise & Resubmit" action just cost more than the average assistant project manager's quarterly salary.

Downstream Trade Disruption

Submittal schedule delays don't exist in isolation. They create cascade effects:

Trades work out-of-sequence, destroying labor productivity at the job site

Crews stand idle waiting for an approved submittal

Coordination problems multiply across disciplines

Rework becomes necessary when project teams guess instead of waiting

Relationship Damage

Frequent rejections strain relationships throughout the project lifecycle with:

Owners: Who see delays and wonder about your project controls

Architects: Who waste time reviewing non-compliant submissions that don't meet design intent

Subs: Who get frustrated with unclear feedback or excessive scrutiny

These relationship costs are hard to quantify but very real. They show up as:

Fewer repeat clients

More contentious change order negotiations

Difficulty attracting quality trade partners

Higher insurance premiums due to claims history

How Do Submittal Rejections Impact Project Budgets?

Submittal rejections impact project budgets in four primary ways:

Direct costs include the administrative burden of reprocessing rejections, expedited shipping fees when schedule compression is necessary, acceleration costs from compressing the approval process, and the labor costs of multiple rejection cycles.

Schedule costs manifest as Extended General Conditions when critical path delays push out substantial completion, liquidated damages if contractual deadlines are missed, and the premium costs of schedule compression activities.

Productivity losses emerge from out-of-sequence work that destroys labor efficiency, idle crews waiting for submittal approvals, and the coordination chaos that ripples across trades at the job site.

Opportunity costs represent the projects you didn't bid because your team was buried in submittal rework, the margin you couldn't capture because your overhead was inflated, and the innovation you didn't pursue because you were fighting fires.

For most projects, the visible costs (direct and schedule impacts) represent only 60-70% of the true financial burden. The invisible costs (productivity losses and opportunity costs) represent the remaining 30-40%.

Understanding the complete construction submittal review process is essential to identifying where these hidden costs emerge.

How Much Time Do Submittal Rejections Add to Projects?

Each submittal rejection adds 2-4 weeks minimum to your project timelines on average.

Here's why:

The initial review takes 7-14 days (contractual standard). When rejected, the contractor must go through the submittal revision process:

Receive and parse the rejection comments (1-2 days)

Source replacement products or gather missing installation instructions (3-7 days)

Prepare and resubmit the corrected package (1-2 days)

Wait for the design team's second review to reach final approval (7-14 days again)

That's 12-25 days minimum for a single rejection cycle. And roughly 15% of rejected submittals get rejected again on second submission, adding another rejection cycle.

Complex equipment submittals, like a mechanical equipment submittal, often take 2-6 weeks minimum from initial submission to final approval, with shop drawings taking even longer.

For items on the project's critical path - structural steel, MEP equipment, building envelope systems - these delays directly push out your completion date. For non-critical path items, they consume schedule float that you might need later when real problems emerge.

Real Project Impact: A Case Study

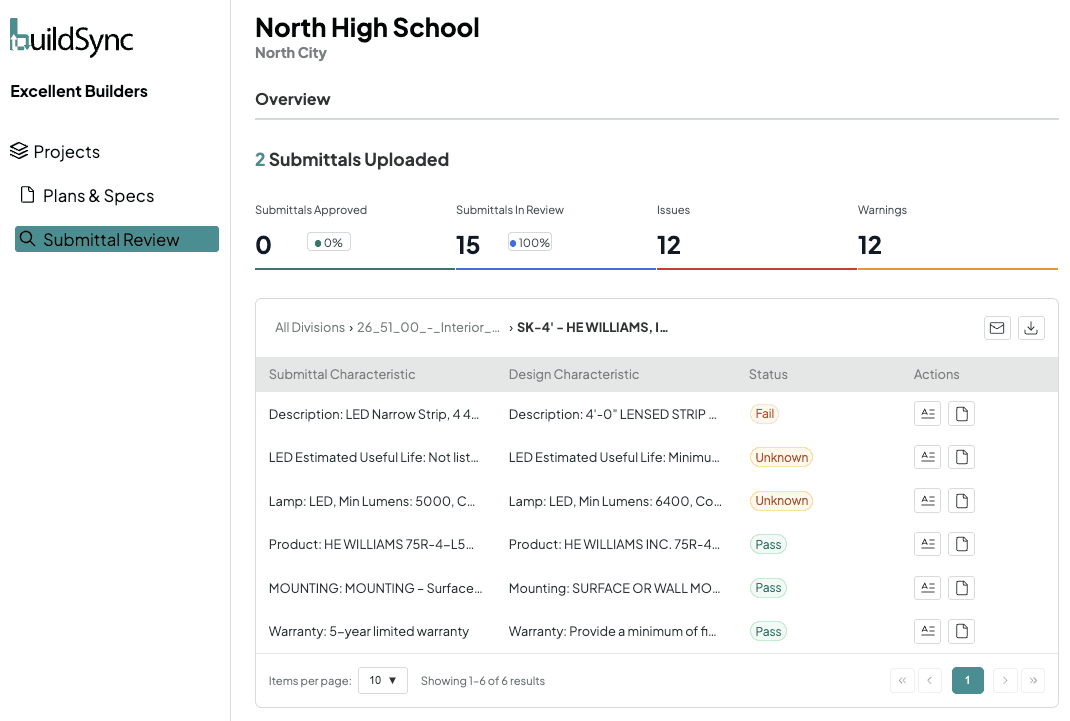

Daniel Recktenwald, PM at Monteith Construction, described the challenges of managing submittals before implementing BuildSync:

"Before BuildSync we were moving through submittals like quicksand, often overwhelmed and missing problems. After BuildSync, submittals have become something that is part of your day and not your whole week."

Monteith's experience mirrors what we see across customers: 70% faster submittal reviews and rejection rates dropping from 30-35% down to less than 5%.

For a project processing 500 submittals:

Traditional approach:

500 submittals × 35% rejection rate = 175 rejections

175 rejections × $805 = $140,875 in rejection costs

Plus 20+ hours per week of PE time on manual reviews

With BuildSync:

500 submittals × 5% rejection rate = 25 rejections

25 rejections × $805 = $20,125 in rejection costs

Annual savings: $120,750 per 500-submittal project

And that's just the direct cost savings. The time savings allow PEs to focus on coordination, problem-solving, and quality control - the work they're actually trained for.

How BuildSync Transforms Submittal Economics

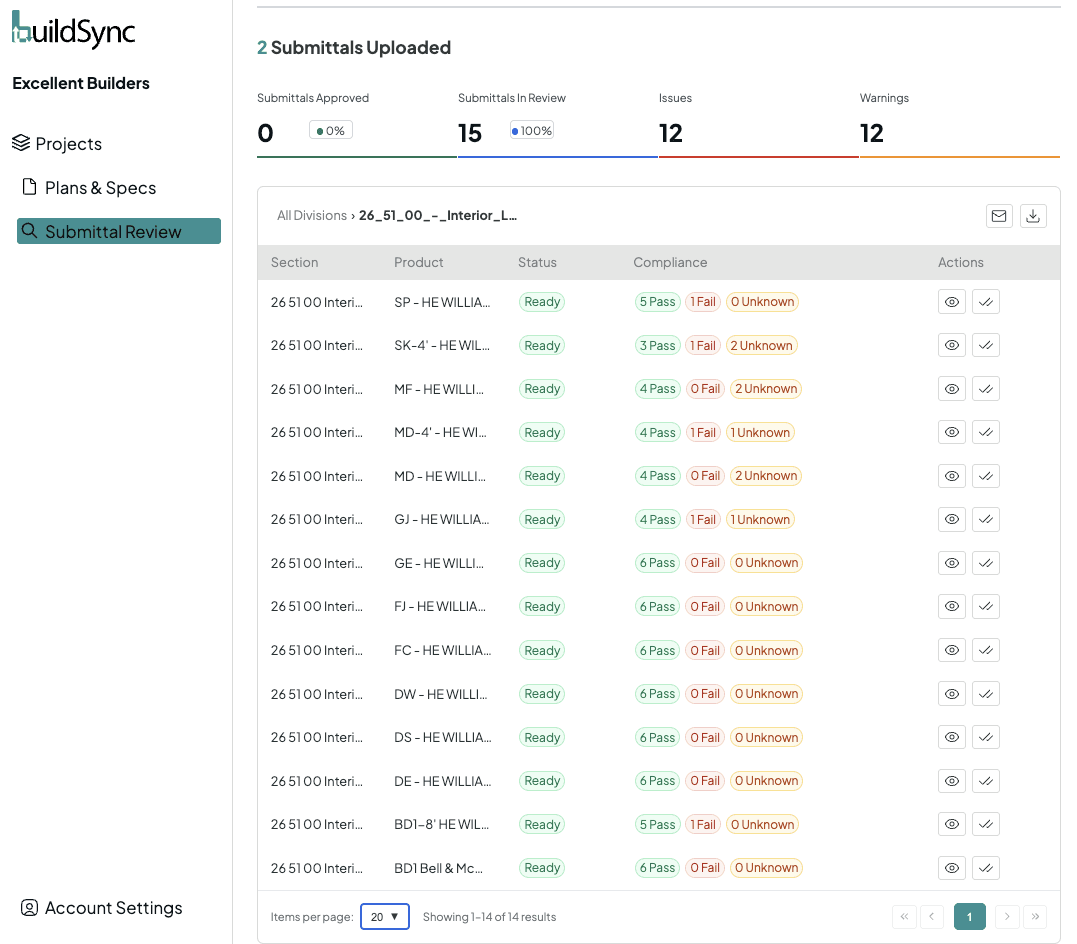

BuildSync addresses the root causes of submittal rejections through automated technical review.

Our AI-powered platform:

Extracts all technical characteristics from submittals (dimensions, materials, ratings, performance specs)

Compares each data point against your project specifications systematically

Flags non-compliant items before they reach the design team

Provides detailed reports showing exactly what's compliant and what's not

The result: Teams catch issues during the review process - when they're easy and cheap to fix - instead of after the design team has spent time reviewing and rejected it.

While some companies are skeptical about AI tools, they can be of great help, if used correctly. Luke says:

AI tools are still just tools. Like any other tool, they require proper training and understanding. And if used correctly, they can greatly increase efficiency.

The Numbers: What BuildSync Customers Achieve

For that same company, processing 2,000 submittals annually:

Traditional approach:

600 rejections (30% rate) × $805 = $483,000 in rejection costs

20+ hours per week of PE time on reviews

With BuildSync:

100 rejections (<5% rate) × $805 = $80,500 in rejection costs

PE time reduced by 70-80% and refocused on high-value activities

Annual savings: $402,500

This doesn't even account for improved submittal approvals, relationship benefits, and competitive advantages that come from demonstrating superior project management to clients.

Metric | Traditional Manual Review | BuildSync Automated Review | Improvement |

Rejection Rate | 30-35% | <5% | 83-86% reduction |

Average Review Time per Submittal | 2-4 hours | 0.5-1 hour | 70-75% faster |

PE Hours per Week on Submittals | 20-30 hours | 5-8 hours | 70-75% time savings |

Cost per 1,000 Submittals | $241,500 (at 30% rejection) | $40,250 (at 5% rejection) | $201,250 savings |

Schedule Impact | 2-4 weeks added per rejection | Minimal (issues caught pre-submission) | Critical path protection |

Approval Cycle | 14-21 days (often multiple cycles) | 10-14 days (single cycle typical) | Faster project timelines |

Team Capacity | Overwhelmed, reactive | Proactive, strategic focus | Higher value work |

Five Proven Strategies to Reduce Submittal Rejections

Reducing your rejection rate from 35% to 5% isn't magic - it's process discipline combined with the right tools. Here are five strategies that consistently drive down rejection rates based on what we've seen working across hundreds of projects.

1. Implement a Mandatory Contractor Self-Review

The single biggest cause of rejections is contractors skipping their own initial review. Before any submittal leaves your office, require a documented preliminary review against specifications.

Action steps:

Create a simple submittal checklist that mirrors specification requirements

Assign responsibility: Who on your team performs the preliminary review before submission?

Document the review: Add a cover sheet showing which specifications were checked

Make it visible: Let the GC know you've performed your own quality check

This strategy alone can cut your rejection rate in half. When contractors review their own work first, they catch the obvious non-compliance issues - wrong products, missing data, incomplete certifications - before wasting everyone's time.

2. Front-Load Critical Submittals

Don't wait until you need submittal approvals to start the approval process. For items on your project's critical path, submit for review during buyout - before you even need approval.

Critical path items to front-load:

Structural steel connections and embedded items

Long-lead MEP equipment (switchgear, chillers, boilers)

Building envelope systems (curtain wall, roofing)

Custom millwork or specialty fabrication with comprehensive shop drawings

Any item with lead times exceeding 16 weeks

This approach eliminates the "we're waiting on submittal approval" excuse from your schedule. If issues arise, you have adequate review time to resolve them without triggering critical path delays.

3. Standardize Your Submittal Package Format

Inconsistent submittal formats force reviewers to hunt for information, increasing review time and rejection likelihood. Create a standard template that makes compliance checking easy.

Essential elements of a good submittal package:

Cover sheet with specification section references

Compliance matrix showing each requirement and where it's addressed

Product data sheets with relevant sections highlighted

Installation instructions and certifications clearly marked

Specification excerpts for easy cross-reference

The goal is making the reviewer's job easier. When they can quickly verify compliance, they're more likely to approve - and less likely to reject for minor formatting issues.

Download our free MEP submittal review checklist below:

4. Establish Clear Communication Channels with Design Teams

Many rejections stem from miscommunication or differing interpretations of specifications. Set up proactive communication before submittals become problems.

Communication strategies that work:

Schedule a pre-submittal conference for complex systems

Submit preliminary product selections for informal feedback

Ask clarifying questions via RFI before submitting

Request specification interpretations regarding design intent in writing

Build relationships with reviewing architects and engineers

This collaborative approach transforms the review process from adversarial to cooperative. Design teams appreciate contractors who engage early, and they're more likely to work with you on solutions rather than defaulting to rejection.

5. Automate Technical Compliance Checking

Manual review processes can't keep pace with modern construction submittals. A typical commercial project involves thousands of data points that need verification against specifications - far more than any person can systematically check when tracking submittals across multiple projects.

This is where automation delivers transformative results. Automated submittal review systematically extracts every technical characteristic from construction submittals and compares them against specifications - catching the details that slip through manual reviews.

What automation catches that manual reviews miss:

Dimensional conflicts buried in 70-page cut sheets

Performance specifications that don't quite meet minimums

Missing certifications or test reports

Product substitutions that weren't formally approved

Specification references to wrong sections or outdated standards

The key advantage isn't just speed - it's consistency. Automated systems check every data point every time, regardless of reviewer workload, experience level, or time pressure.

Implementing These Strategies Sequentially

You don't need to implement all five strategies simultaneously. Start with the quick wins:

Immediate (Week 1): Implement mandatory self-review checklists

Short-term (Month 1): Standardize your submittal package format

Medium-term (Quarter 1): Front-load critical path submittals in your submittal schedule

Ongoing: Build communication protocols with design teams

Strategic: Evaluate automation tools for systematic compliance checking

Each strategy builds on the others. Self-review catches obvious issues. Standardized formats make review efficient. Front-loading prevents schedule impacts. Communication prevents misunderstandings. And automation ensures nothing falls through the cracks.

The teams achieving rejection rates below 5% aren't doing one thing differently - they're doing all five things consistently. That's the difference between fighting submittal fires on every project and having submittals become a routine, manageable part of your workflow.

Strategy | Implementation Timeline | Difficulty Level | Expected Rejection Rate Reduction | Additional Benefits | Investment Required |

Mandatory Self-Review | Week 1 | Low | 10-15% reduction | Improved sub quality, fewer RFIs | Time only (no cost) |

Standardized Package Format | Month 1 | Low | 5-8% reduction | Faster reviews, better documentation | Template creation time |

Front-Load Critical Submittals | Quarter 1 | Medium | Protects critical path | Schedule certainty, reduced risk | Process change management |

Design Team Communication | Ongoing | Medium | 5-10% reduction | Better relationships, fewer disputes | Time investment in coordination |

Automated Compliance Checking | 2-4 weeks | Low (with right tool) | 20-25% reduction | 70-80% time savings, consistency | Software investment |

All Strategies Combined | 3-6 months | Medium | 25-30% total reduction (to 5-10% rejection rate) | Transformed workflow, competitive advantage | Moderate (high ROI) |

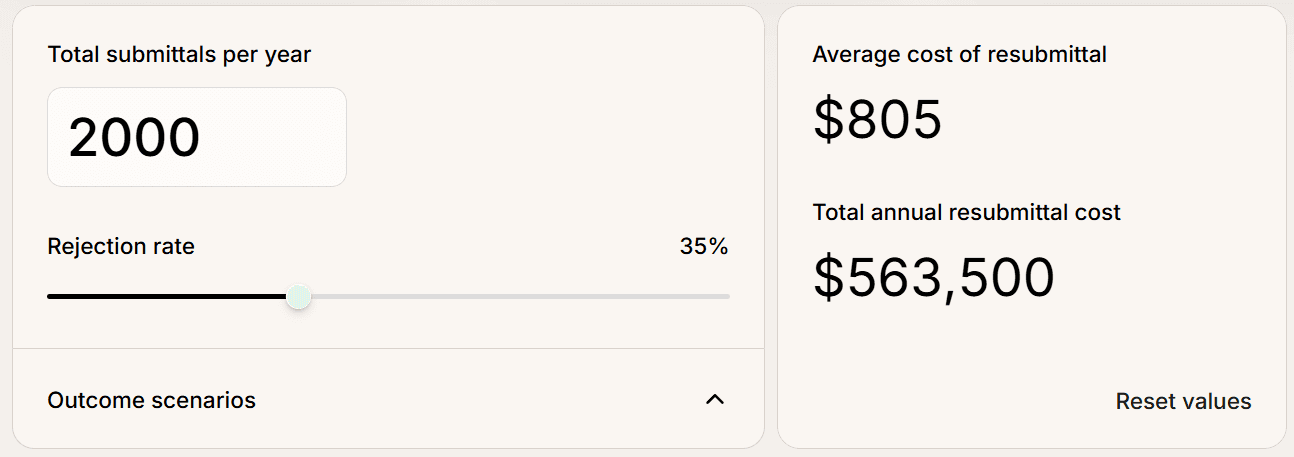

Calculate Your Submittal Rejection Costs

Every company's situation is different. That's why we built an interactive ROI calculator that lets you input your specific numbers:

How many submittals do you process annually?

What's your current rejection rate?

What's your average project schedule?

The calculator uses our research-backed methodology to show your potential annual losses - and more importantly, your potential savings with improved submittal management.

Try our free ROI calculator to see your potential savings.

The Bottom Line on Submittal Rejection Costs

At an average cost of $805 per rejection, submittal issues aren't just administrative hassles - they're material threats to project profitability. When 30-40% of your construction submittals get rejected, you're systematically eroding margins that are already thin.

The question isn't whether you can afford to improve your submittal process. The question is whether you can afford not to.

The cost of submittal rejection hits projects three ways: the direct $805 per rejection, the schedule delays that extend general conditions, and the downstream productivity losses that ripple across trades. Together, these costs can easily reach $500,000+ annually for a mid-sized contractor.

But here's the good news: this is one of the most solvable problems in construction. Unlike weather delays or unforeseen site conditions, submittal rejections are entirely preventable. The technology exists to catch non-compliant items before they reach the design team. The ROI is immediate and measurable. And the competitive advantage is significant - companies demonstrating superior submittal processes win more work and command better margins.

Ready to eliminate your submittal rejection costs?

Frequently Asked Questions

Related reads for you

Discover more articles that align with your interests and keep exploring.