Construction Technology & Innovation

/

Jan 15, 2026

What Are Construction Specifications? (2026 Guide)

Learn what construction specifications are, why they matter, and how they guide every project. Includes spec types, divisions, and how they work with drawings.

Every submittal rejection adds 2+ weeks to your timeline. Every rework cycle eats into your margins. And more often than not, the root cause traces back to a single source: specification in construction requirements that were misunderstood, overlooked, or never properly reviewed in the first place.

Construction specifications are the most critical project documents that nobody wants to read. They're dense, technical, and essential to getting construction projects built right the first time. Yet across the construction industry, project teams struggle with the same challenge: how to effectively review specifications against submittals without spending days combing through hundreds of pages of technical requirements.

This guide breaks down everything you need to know about construction specifications - from what they are and why they matter, to how modern teams are transforming the spec review process from tedious manual work into strategic verification.

What Are Construction Specifications?

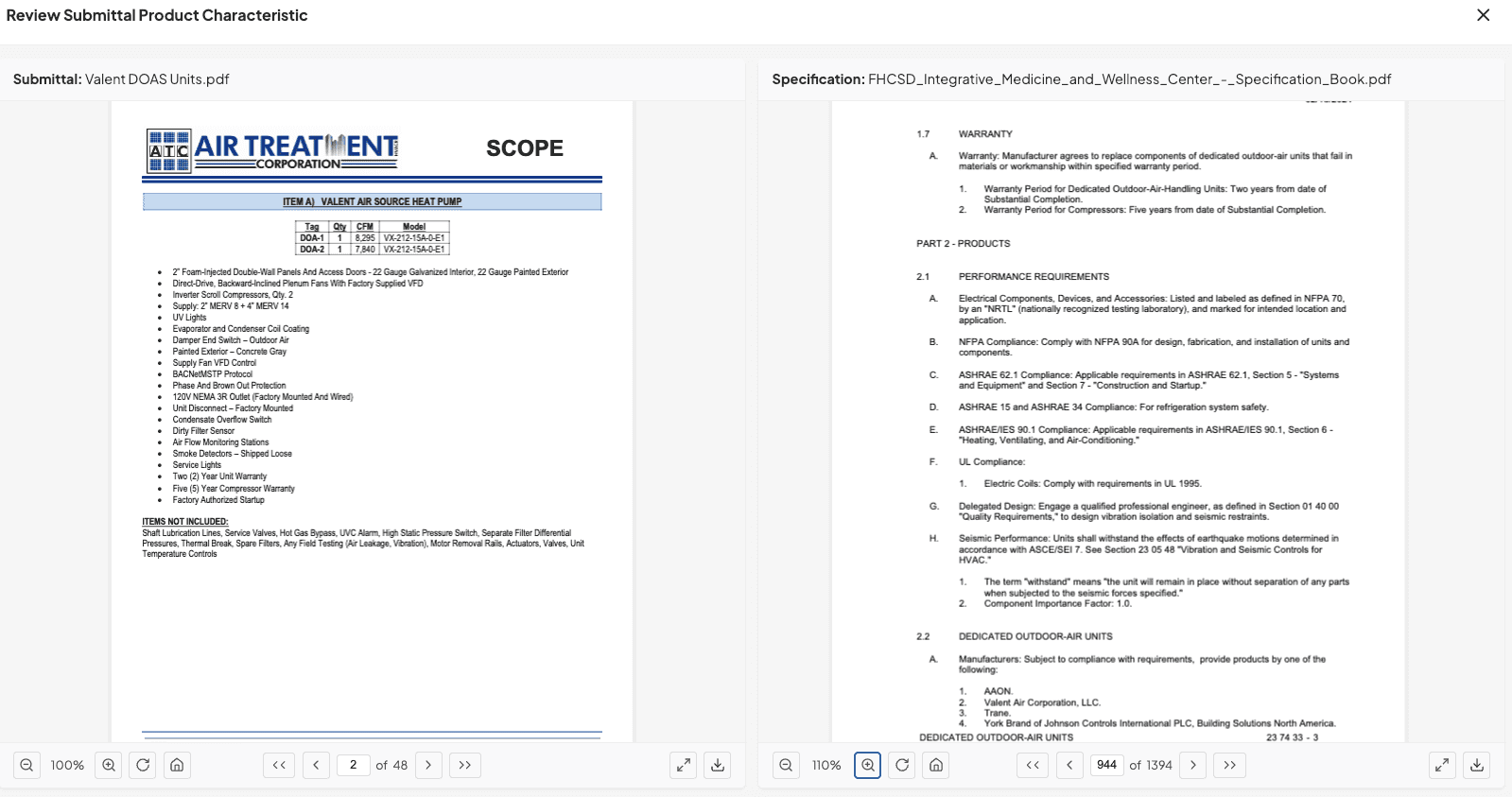

Construction specifications are written technical documents that define quality standards, performance criteria, and characteristics of materials, equipment, and workmanship required for a construction project. While architectural drawings show where things go and what they look like, construction specs describe what those things must be and how they must perform.

Think of specs as the "project terms within the contract." Drawings tell you to install an air handling unit in a specific location. Specifications tell you that unit must be a 10,000 CFM capacity rooftop unit with R-410A refrigerant, 13 SEER minimum efficiency, factory-installed economizer, and a 10-year manufacturer warranty.

Those project details - the ones that determine whether equipment actually meets project requirements - live in the specifications.

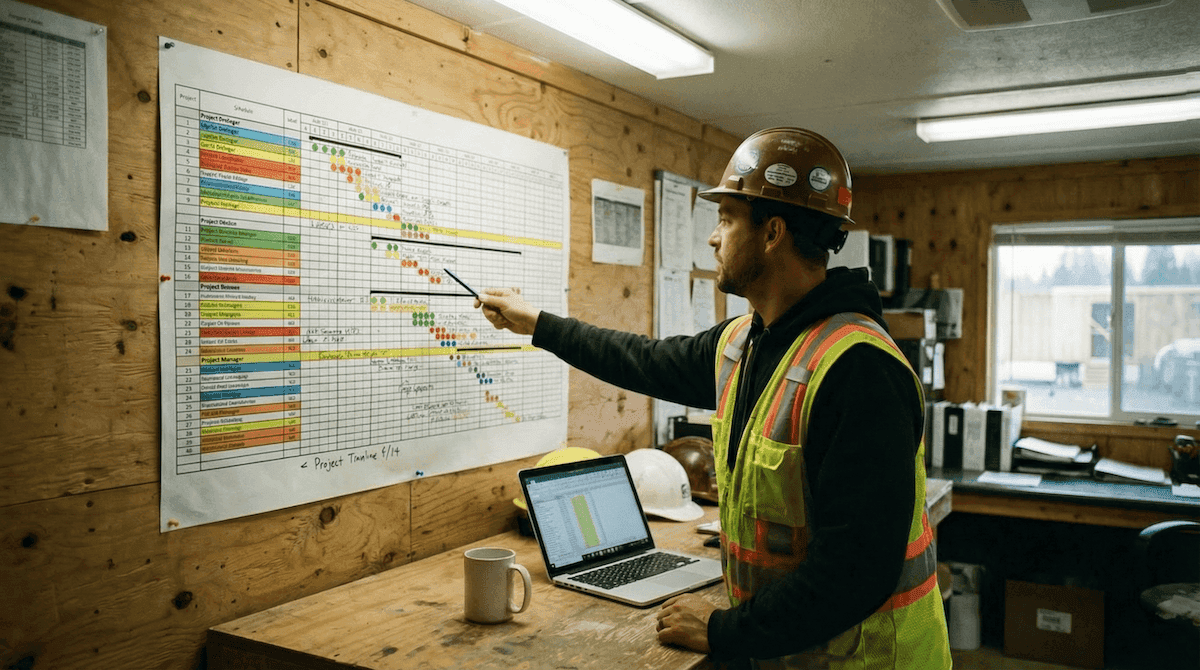

Who Handles Construction Specs?

Construction specifications are typically prepared by architects or designers during the design phase - before the construction phase begins - often with input from project engineers or professional specification writers. These detailed written documents serve as powerful information hubs for project stakeholders, ensuring every detail is specified without room for misinterpretation or error.

As a technical narrative accompanying visual drawings, specifications bridge the gap between what architects and engineers envision and what gets erected and installed, providing explicit instructions to guide contractors' work and parameters that stakeholders can reference to check built work against during inspections.

Specs in construction translate design intent into verifiable technical requirements. Without clear specifications, every construction project becomes a guessing game about what meets construction requirements and what doesn't.

Luke Paulo, the co-founder of BuildSync, says that the most common misconception about construction specifications that ultimately leads to problems is that they are comprehensive.

That they are comprehensive. They need to be considered with the drawings to paint the complete picture.

Modern specification documents have evolved significantly from written instructions on drawings.

The Construction Specifications Institute (CSI) introduced the first standardized format in 1963, creating a common language for structuring construction specifications across the construction industry. Today, specifications follow structured formats that organize requirements consistently across all project types.

The challenge? Construction specs for commercial projects routinely run 50-300+ pages. Finding every relevant requirement and verifying it against submittal data is exactly the time-consuming, detail-intensive work that construction companies struggle to fit into already packed schedules.

Why Are Construction Specs Important?

Building specifications aren't just documentation - they're legally binding documents that define responsibilities and expectations for all parties involved in a project. Understanding specifications in construction is critical because these documents serve as the foundation of quality assurance, accurate cost estimations, and legal protection on every construction project.

Legal Protection and Construction Contract Compliance

Specifications form part of the construction terms documents. When disputes arise about whether work meets contract requirements, specifications provide the definitive answer.

Did the contractor deliver what they were contractually obligated to provide?

The spec says yes or no. Specifications detail the scope and methods of work, materials, workmanship, permits, and timelines for a project that will be placed under contract. This legal weight makes thorough spec review non-negotiable for general contractors and specialty contractors alike.

Quality Standards and Performance Requirements

Construction specifications establish the baseline for acceptable project quality, providing clear instructions for contractors, suppliers, and subcontractors to ensure quality, consistency, and compliance throughout the construction process. They define performance criteria, testing requirements, and installation standards that determine whether systems will function per design intent.

Specifications also provide benchmarks for inspectors and project managers to verify compliance with performance and quality standards. When specs call for 13 SEER minimum HVAC efficiency and a 12 SEER unit gets installed, the building won't perform to design standards - and the owner won't get the final product they paid for.

Cost Predictability and Risk Management

Unclear or incomplete specifications create project cost uncertainty. When requirements are ambiguous, construction crews make assumptions - and those assumptions often prove expensive. Research shows that rework costs account for 4-10% of total construction costs, with design-related issues (including specification errors and omissions) causing up to 70% of that rework.

Detailed construction specifications significantly improve the accuracy of cost estimations, helping avoid budget overruns. They also minimize change orders by ensuring all necessary information is provided upfront.

The hidden cost overruns of poor specification management extend beyond direct rework: project engineers spending 20+ hours per week reviewing submittals against specs, each submittal rejection adding 2+ weeks to the timeline, industry average rejection rates hovering around 30-40%, and critical items getting overlooked until project completion.

Specifications also outline necessary safety protocols, reducing accidents and potential failures during the building process. These aren't theoretical concerns. Construction teams encounter these challenges on virtually every complex project.

The problem isn't that specs don't matter - it's that thorough specification review requires more time and technical knowledge than most teams can consistently provide.

Ready to reduce your submittal review time by up to 80%? Learn how BuildSync helps teams verify submittal compliance against specifications in hours instead of days. Schedule a demo.

Types of Construction Specifications: Performance, Prescriptive, and Proprietary

The three main types of construction specifications are performance specifications, prescriptive specifications, and proprietary specifications, each serving different project needs and allocating risk differently between owners and contractors.

Understanding these types matters because each requires different verification approaches during submittal review.

Performance Specifications | Prescriptive Specifications | Proprietary Specifications | |

What They Define | Desired outcomes, functional requirements, and structural and performance requirements without dictating specific materials or installation methods | Exact materials, methods, procedures, and installation requirements | Specific manufacturers, model numbers, or products required |

Examples | "HVAC system shall maintain indoor temperature at 72°F ±2° with relative humidity between 40-60% under all design load conditions." | "Install 2x6 Douglas Fir studs at 16 inches on center. Studs shall meet or exceed No. 2 grade per Western Wood Products Association grading rules. Install per AWC National Design Specification and construction codes." | "Trane Voyager HVAC unit, model RTU-125, or approved equal from Carrier, Lennox, or York." |

Verification Challenge | Requires analyzing technical data to confirm equipment can meet performance criteria. Site engineers must verify unit capacity, efficiency ratings, and control capabilities against building load calculations - not just check for a specific model number | Generally easier - prescriptive construction specifications list exactly what's required; submittals must match those requirements. But "easier" is relative when specs run hundreds of pages with dozens of requirements per equipment type | The initial check is simple (does it match the specified product?). But when alternatives are proposed with "or equal" language, verification becomes complex - requiring point-by-point comparison of technical characteristics to prove equivalency |

Pros |

|

|

|

Cons |

|

|

|

Each specification type affects the automated submittal review process differently. Performance specifications require analyzing technical data to verify capability. Prescriptive specifications need point-by-point requirement checking. Proprietary specs with "or equal" clauses demand comprehensive equivalency analysis.

The complexity compounds when construction projects mix all three types, which most do. A mechanical spec section might use proprietary specs for critical HVAC equipment, performance specifications for energy efficiency standards, and prescriptive specifications for proper installation procedures. A thorough review means checking every requirement type against the submittal data.

Understanding CSI MasterFormat: Organizing Construction Specifications

If you've ever wondered why all construction specifications look similar, you can thank the Construction Specifications Institute (CSI) and its MasterFormat system. MasterFormat provides the standardized organizational framework that the construction industry uses to structure project specifications and construction documents.

Think of MasterFormat as the Dewey Decimal System for construction. Division 03 always covers concrete, Division 23 always covers HVAC, and Division 26 always covers electrical. This consistency means project teams can quickly navigate specifications regardless of who wrote them.

Key Elements in Common Construction Divisions

While all 50 divisions exist, certain divisions dominate in typical commercial building projects:

Division 01: General Provisions and Project Requirements covers administrative requirements, submittal procedures, quality control standards, and project finalization requirements.

Divisions 03, 08, 09: Concrete materials and procedures (03), doors and windows (08), and finishes like flooring and coatings (09).

Division 21-23: Mechanical includes fire suppression systems (Division 21), plumbing fixtures and piping (Division 22), and HVAC equipment and ductwork (Division 23).

Getting 30-40% of your plumbing submittals rejected by the design team? BuildSync's plumbing submittal review software catches non-compliant fixtures, pipe materials, and equipment specs before they reach your architect - reducing your rejection rate to 5% and saving weeks on your timeline.

Division 26: Electrical handles electrical service and distribution, lighting fixtures and controls, and emergency procedures and power systems.

The division structure directly influences submittal review workflows. PMs typically organize submittal logs by division. When BuildSync processes submittals, the system can automatically identify relevant spec divisions and extract requirements accordingly.

The standardized structure provides consistency, but even with well-organized specifications, individual divisions still run 50-100+ pages, and finding every relevant requirement across multiple divisions takes hours.

For more details, the official CSI MasterFormat documentation provides comprehensive guidance on division structure and updates.

What Construction Documents Look Like: Structure and Key Elements

Construction specifications are typically organized as written documents in a three-part section format covering General, Products, and Execution requirements, formatted according to CSI standards and organized by division.

Opening a spec book, you'll find construction specifications serving as legally binding contract documents that establish performance standards and provide a reference point for resolving disputes. The structure typically includes:

The Three-Part Section Format

Every specification section follows the same three-part structure, making information findable once you know where to look:

Section Part | What It Covers |

Part 1: General |

|

Part 2: Products |

|

Part 3: Execution |

|

Key Elements of Construction Specifications

Effective construction specifications contain several essential components that work together to define project requirements comprehensively. Understanding these key elements helps all project stakeholders - from contractors and construction crews to project managers and inspectors - recognize what information governs every aspect of the build.

General Information and Project Scope

Part 1 of every specification section establishes the foundation: project scope, related sections, submittal requirements, and general provisions. This is where you'll find what specific documentation must be provided - product data sheets, test reports, certifications, and warranties.

Missing required submittals results in automatic rejection. General information also covers delivery and storage requirements, project conditions, and coordination with other trades.

Material and Product Requirements

Part 2 defines the technical heart of specifications: performance criteria (capacities, efficiencies, ratings), specific materials and their characteristics, manufacturer requirements and acceptable alternates, and required certifications and testing standards.

This section answers what products can be used, from whom they must be sourced, and what technical characteristics they must possess. For proprietary specs, this is where acceptable manufacturers are listed - typically at least three to maintain competition and control project costs.

Workmanship Expectations and Installation Standards

Part 3 establishes how equipment must be installed, tested, and commissioned. These workmanship expectations cover installation procedures, field quality control, proper installation methods, and coordination requirements. Often overlooked during initial submittal review, these standards become critical during field verification and commissioning. They define acceptable installation tolerances, mounting requirements, connection specifications, and protection of completed work.

Quality Requirements and Testing Protocols

Specifications establish quality standards through detailed testing protocols, inspection requirements, and acceptance criteria. These quality requirements include specific testing standards (UL, ASTM, ASHRAE, etc.), third-party certifications, performance testing procedures, and verification methods.

Commonly missed items like spare parts requirements, O&M manual specifications, and training requirements surface here - often causing retention delays during closeout if overlooked initially.

Relevant Codes and Industry Standards

Building codes and industry standards referenced throughout specifications ensure regulatory compliance and safety standards. These references establish minimum requirements for materials, installation methods, testing procedures, and performance thresholds.

Specifications cite specific code editions and standard revisions to eliminate ambiguity about which requirements apply. This includes local building codes, fire safety codes, accessibility standards, and industry-specific regulations.

Payment Terms and Warranty Requirements

Warranty durations, coverage terms, and service contract requirements appear in multiple specification locations - Division 01 general requirements, specific equipment sections, and closeout requirements. Payment terms related to submittal approval milestones, inspection requirements, and substantial completion criteria establish the financial framework.

Extended warranty requirements, maintenance agreement terms, and warranty documentation submittals define long-term project obligations.

Environmental Considerations

Modern specifications increasingly address environmental regulations and sustainable building practices. The 2026 specifications mandate low-VOC materials, waste management procedures, recycling requirements, and energy efficiency standards.

Environmental considerations include material sourcing requirements, construction waste disposal protocols, indoor air quality protection during construction, and compliance with green building certification programs like LEED.

Other Unique Considerations

Project-specific requirements vary based on building type, owner preferences, and site conditions. These might include security requirements for government projects, infection control protocols for healthcare facilities, operational continuity requirements for occupied renovations, or historical preservation standards for existing building work.

Specification documents also address personal protective equipment requirements, emergency procedures, and site-specific safety protocols that go beyond standard building codes.

The challenge project teams face is systematically extracting every relevant requirement from these key elements, matching them against submittal data, and documenting compliance across dozens (sometimes hundreds) of technical characteristics per equipment type. Understanding how these elements work together - and where critical requirements hide across multiple specification sections - determines whether submittals get approved on the first review or enter costly rejection cycles.

When managing complex specification requirements across multiple divisions and trades, a construction submittal template ensures systematic tracking of compliance checkpoints and approval workflows throughout the review process.

When asked about the most commonly missed requirements that cause submittal rejections, Luke Paulo, the co-founder of BuildSync, says:

Requirements vary drastically across division and product type, however, since manufacturer and warranty requirements are checked for each product, these tend to be the most common rejections.

Best Practices for Specifications in Construction

Writing effective construction specifications requires balancing completeness with clarity. Specifications in construction serve as a legally binding guide throughout the project lifecycle, so getting them right during the design phase prevents costly issues during construction and closeout.

Use Clear, Measurable Language

Avoid vague terms like "adequate" or "suitable." Use specific, measurable criteria: "minimum 85% efficiency" rather than "high efficiency," or "concrete compressive strength shall achieve 4,000 psi at 28 days."

Clear language ensures all project participants - from contractors and construction crews to inspectors - understand exactly what's required, preventing misunderstandings that lead to errors and rework.

Follow Standard Formats for Organizing Construction Specifications

Use the CSI three-part section format consistently: Part 1 (General requirements, submittal procedures, quality standards), Part 2 (Products, materials, equipment specifications), and Part 3 (Execution procedures, installation methods, field quality control).

This standardized structure, organized by CSI MasterFormat divisions, helps contractors quickly locate information and improves accurate budgeting.

Balance Performance and Prescriptive Requirements

Choose the appropriate specification type based on project needs. Performance specifications give contractors flexibility while ensuring results - use them when multiple solutions could work. Save prescriptive construction specifications for situations where specific methods are necessary due to building codes or design intent.

Maintain Competition and Clarity

For proprietary specifications, include at least three acceptable manufacturers to maintain genuine competition and reasonable costs. Clearly define submittal requirements in Part 1 of each section - list exactly what documentation contractors must provide: product data sheets, test reports, certifications, warranties. Eliminating ambiguity about what constitutes a complete submittal reduces rejection cycles.

Keep Specifications Current

Don't rely on years-old master specifications. Verify that specified manufacturers and products are still available and that referenced codes reflect current requirements. The 2026 specifications increasingly mandate low-VOC materials and eco-friendly building practices to meet rising environmental regulations.

Coordinate and Review Regularly

Check for conflicts between specification sections and between specifications and construction drawings before issuing construction terms documents. Construction specifications should be reviewed and updated regularly throughout design development to ensure they remain current and reflect any changes in materials, codes, or safety standards.

Write for the Field

Write specifications that can actually be verified and built, not just in theory. Consider the construction workflow and ensure specifications align with realistic field conditions. Make warranty terms, spare parts requirements, and testing protocols explicit - don't assume everyone knows what's required. This explicit detail allows contractors to accurately price the work and eliminates surprises during closeout.

Well-written construction specifications improve communication among project stakeholders, serve as legally binding documents that define responsibilities, and provide benchmarks for project managers to verify compliance with performance and quality standards. Investing time in thorough specification writing during the design phase prevents exponentially more time spent resolving conflicts and managing change orders during construction.

How to Review Construction Specs: Manual vs. Modern Approaches

Effective specification in construction review requires systematic extraction of technical requirements, verification against submittal data, and documentation of compliance - a review process that traditionally takes hours but can be automated to save up to 80% of review time.

The Traditional Manual Review Process

A comprehensive specification review done manually involves five steps:

Read Through Entire Spec Section (30-60 minutes): Review the full section, identify applicable requirements, and note cross-references

Extract and Organize Requirements (45-90 minutes): Create a compliance checklist or spec sheet

Review Submittal Product Data (30-60 minutes): Read through submittal documentation, locate technical data for each requirement

Point-by-Point Comparison (60-120 minutes): Compare each submittal data point against spec requirements, document pass/fail/unknown

Document Findings (30-45 minutes): Prepare review comments, mark up submittal with issues

Total time per submittal: 3-6 hours for moderately complex projects. Total time for an air handling unit: 6-8 hours.

On a typical commercial project processing 500-2,000 submittals, the math gets painful quickly.

Important Aspects to Look for During Specification Review

Technical Characteristics: Dimensions, performance ratings (capacity, efficiency, output), load ratings, structural requirements, and electrical characteristics.

Specific Materials and Finishes: Materials of construction, coating and finish requirements, fire ratings, and certifications.

Performance Criteria: Energy efficiency ratings (SEER, EER, efficiency percentages), load capacities, and operating parameters.

Manufacturer Requirements: Acceptable manufacturers and models, "or equal" substitution criteria.

Testing and Regulatory Compliance: Required testing standards (UL, ASTM, ASHRAE, etc.), third-party certifications, and agency approvals.

Installation Methods: Mounting and support specifications, clearance requirements, and coordination with other systems.

Warranty and Spare Parts: Warranty duration and coverage, spare parts quantities, O&M manual requirements, and training requirements.

An air handling unit might have 40-60 technical characteristics requiring verification. A lighting fixture submittal covering 50 fixtures might require checking 300+ individual data points.

Modern Approaches to Specification Review

Teams are reimagining how to review construction specs, moving toward approaches that maintain thoroughness while dramatically reducing time investment:

AI-Powered Compliance Checking: Automated submittal review platforms can extract technical characteristics from submittals and compare them against specification requirements in hours instead of days - freeing project teams to focus on judgment calls and coordination.

Hybrid Review Workflows: The system handles tedious data comparison. The project manager or PE reviews the findings, applies project-specific judgment, and makes the final approval decision.

Reviewing construction specs effectively in 2026 means leveraging technology to handle systematic verification while maintaining human oversight for judgment and context. Teams that adopt this approach report dramatic time savings while catching more compliance issues than manual review alone.

See how BuildSync automates specification review without replacing your judgment. Extract every technical requirement, verify every data point, and document compliance in hours instead of days.

Common Construction Specification Pitfalls and How to Avoid Them

Beyond these common pitfalls, many issues stem from teams not being properly trained to access and use construction specifications effectively. Training teams on specification navigation and review processes can significantly enhance project outcomes and reduce errors throughout the project lifecycle. Here's how problems manifest and how to prevent them:

For Design Teams During the Design Phase

Conflicting Requirements Between Divisions: Division 23 specs call for R-410A refrigerant while Division 01 requires compliance with newer environmental standards mandating R-454B.

Prevention: Coordinate specifications across divisions during the design phase.

Outdated Manufacturer Specifications: Specifying discontinued manufacturers creates immediate submittal challenges.

Prevention: Verify manufacturer offerings during final spec preparation. Update office master specifications regularly.

Unclear Performance Criteria: Performance specifications without measurable criteria create disagreement about compliance.

Prevention: Include specific, measurable performance criteria with clear testing methods.

Overly Restrictive Proprietary Specs: Single manufacturer specs can inflate accurate cost estimations by 15-30%.

Prevention: Include at least three acceptable manufacturers.

For General Contractors

Failing to Verify Submittals Thoroughly: The "rubber stamp" review creates downstream problems. When design teams reject submittals GCs already approved, schedules slide.

Prevention: Implement systematic review processes. Many teams use automated submittal review to ensure thorough verification.

Missing "Or Equal" Requirements: General contractors often fail to verify comprehensive equivalency - missing project details like warranty terms or spare parts.

Prevention: Create equivalency checklists for common equipment types.

Overlooking Warranty Requirements: Warranty specs hide in multiple locations: Division 01 general requirements, specific equipment sections, and closeout requirements.

Prevention: Extract warranty requirements during initial spec review.

Not Catching Conflicts Before Submitting: Finding conflicts after submission costs 2+ weeks per rejection cycle.

Prevention: Conduct a thorough GC-level review before forwarding to design teams.

For Subcontractors

Not Reading Specs Before Procurement: Ordering equipment before verifying specification compliance causes expensive reprocurement.

Prevention: Review specs during the bid phase and before ordering equipment.

Assuming "Close Enough" Is Acceptable: Construction specifications define contract requirements. Close doesn't count.

Prevention: Verify exact compliance. If equipment doesn't match specs exactly, submit an RFI before proceeding.

Missing Supplementary Requirements: Focusing only on equipment specs while missing O&M manual requirements, spare parts specifications, personal protective equipment requirements, or training requirements creates closeout delays.

Prevention: Review Part 3 (Execution) requirements. Track close-out requirements from the beginning of the project timeline.

Ignoring "Or Equal" Approval Processes: Proposing alternates without following proper substitution procedures leads to automatic rejection.

Prevention: Submit formal substitution requests early, including a detailed description demonstrating equivalency.

The Real Impact

These pitfalls have measurable consequences:

35% average submittal rejection rate across the construction sector (BuildSync customers achieve less than 5%)

2+ weeks added to the timeline per rejection for standard resubmission cycles

Cost overruns from expediting fees, replacement equipment, and project delays

As stated earlier, Industry research shows that rework and non-compliance issues cost projects 4-10% of total project costs, with specification-related problems contributing significantly to that waste.

The common thread: incomplete or inconsistent specification verification. When teams lack time or tools to thoroughly review specs against submittals, issues slip through - creating exactly the rejection cycles everyone wants to avoid.

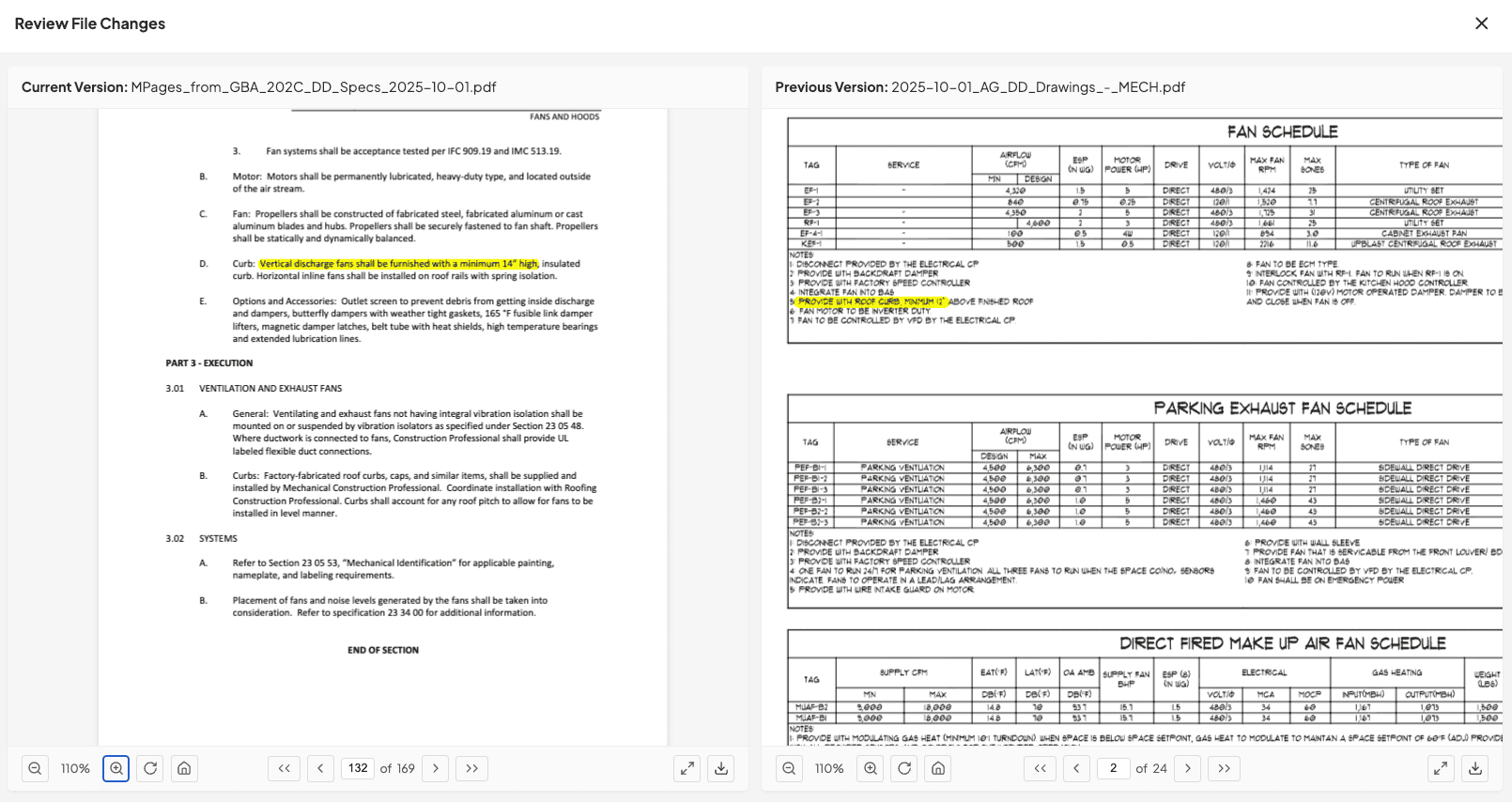

How Specification In Construction Relate to Architectural Drawings

Construction specifications and architectural designs are complementary project documents with distinct but equally important roles. Understanding how specifications relate to drawings - and what to do when they conflict - is essential for thorough submittal review.

Complementary Roles: What Each Document Covers

Architectural Drawings Show: Physical location and layout, dimensions and quantities, visual representations and spatial relationships, and installation location.

Building Specifications: Define technical requirements and performance, materials and quality standards, installation procedures, testing and acceptance criteria, warranty, and service contract requirements.

Think of it this way: drawings answer "where" and "how much." Specifications answer "what" and "how good."

Example: For an HVAC system, drawings show equipment location on floor plans, ductwork routing, and equipment tag numbers (AHU-1, AHU-2), while specifications define equipment capacity, energy efficiency ratings, materials of construction, manufacturer requirements, and installation standards.

Order of Precedence in Building Codes and Standards

When project documents conflict, most contracts establish an order of precedence: (1) Contract modifications and addenda, (2) Specifications, (3) Drawings, (4) Reference standards.

In legal interpretations, specifications generally take precedence over drawings in the event of conflicts. This means that when specifications and drawings disagree, specifications typically govern. But actual precedence depends on contract language, which varies by construction project.

Handling Conflicts Between Specifications and Drawings

Despite best efforts during the design phase, conflicts happen: architectural designs show equipment in locations that don't meet specification clearance requirements, specifications call for one manufacturer while drawings show different equipment, or dimensions don't match minimum sizes in specifications.

The RFI Process for Clarification

When conflicts arise, issue an RFI (Request for Information) that references a specific spec section and drawing sheet/detail, clearly describes the conflict, explains why it matters for the construction process, and requests clarification on which requirement governs. The design team's RFI response becomes a binding interpretation of the project contract documents.

Specification-drawing conflicts create "unknown" compliance situations during submittal review - you can't definitively approve a submittal when documents conflict. This is why thorough pre-construction review of both specifications and architectural drawings pays dividends - catching conflicts before they delay submittals.

The Future of Construction Specifications in the Project Lifecycle

Construction specifications are on the cusp of their biggest transformation since CSI MasterFormat standardization. The role of specification in construction is evolving - not in what it defines, but in how teams create, manage, and verify requirements throughout the project lifecycle.

Digital Specifications and BIM Integration

The construction sector is moving from PDFs toward structured, database-driven specification systems that integrate with Building Information Modeling (BIM). This enables direct connection between 3D model objects and specification requirements, automatic clash detection, real-time specification updates that propagate to all technical documents, and structured data export for submittal verification.

Within five years, structured specifications will be standard practice on most commercial construction projects. Specifications are also evolving to meet current environmental regulations and safety standards.

AI-Powered Specification Review and Compliance Checking

AI is fundamentally changing how teams work with specifications during the construction process.

Traditional approach: Read specs, extract requirements mentally, compare against submittals manually, document findings in spreadsheets.

AI-powered approach: Upload specifications once, let AI extract all requirements systematically, compare submittals automatically, review AI-generated compliance reports showing exactly what passes, fails, or needs clarification.

Construction teams using AI for specification review are reducing review time by 70-80%, catching compliance issues that manual reviews miss, and freeing engineers to focus on coordination and problem-solving instead of data extraction.

Automated Submittal Verification

Rather than PEs manually comparing submittal data against specifications, the system extracts all technical requirements from specifications, extracts all technical data from submittal PDFs, compares systematically, flags compliance issues with source references, and generates detailed reports.

This automation doesn't replace PMs - it augments them. The system handles tedious data extraction and comparison. The PM reviews findings, applies project-specific judgment based on technical knowledge, and makes final approval decisions.

Real-Time Collaboration and Cloud-Based Specification Management

Cloud-based platforms enable multiple team members to review simultaneously, automatic version control, instant distribution when specifications update, and mobile access on the job site - eliminating the "working from old specs" problem and keeping construction crews on the same page.

Making Junior Engineers Effective Faster

There aren't enough experienced project engineers to thoroughly review every submittal on every construction project. The labor shortage means construction companies are hiring less experienced people.

AI specification review helps solve this problem by showing junior engineers exactly what requirements exist in specifications, what characteristics matter for each equipment type, and how to verify compliance systematically - helping them build technical expertise faster through exposure to detailed analysis.

Addressing the Labor Shortage Through Automation

The construction industry faces a severe labor shortage. The solution is to automate tedious work so skilled people can focus on activities that require human judgment.

Specification review is the perfect candidate: it's systematic and rule-based, extremely time-consuming when done manually, requires thoroughness more than creativity, and errors have serious consequences.

Automating specification review doesn't eliminate jobs - it eliminates bottlenecks and lets project teams handle more work without burnout.

Early Adopters Gain Competitive Advantage

We're in the window now for AI-powered specification review - a successful project differentiator.

Teams adopting early are experiencing dramatically lower submittal rejection rates (5% vs. 35% industry average), faster project timelines (eliminating 2-week rejection cycles), better relationships with design teams, higher team capacity (PMs handling more projects without additional headcount), and less project engineer burnout.

As AI adoption becomes standard across the construction industry, these advantages will normalize. But right now, there's a real competitive advantage for teams that embrace the technology and sustainable building practices that support efficiency.

The future of construction specifications isn't about changing what they are - it's about radically improving how teams work with them through the construction process, resulting in a better final product.

Be part of the future of specification review. See how leading construction teams are using BuildSync to transform submittal review from a time-consuming bottleneck into a strategic advantage. Request a demo today!

Conclusion

Specification in construction represents far more than just technical documentation. They're the project contract requirements that determine whether equipment meets project standards, the quality assurance framework that ensures proper performance, and the cost predictability tool that prevents expensive rework and delays.

Understanding how to effectively review specs against submittals directly impacts the project's success. Teams that implement thorough specification review see lower rejection rates, faster timelines, better relationships with design teams and subcontractors, and fewer costly surprises during construction and project closeout.

The construction sector is at an inflection point. Traditional manual specification review doesn't scale to the complexity and pace of modern construction. Teams are drowning in submittal review work, junior engineers lack the expertise to review complex submittals effectively, and the 30-40% industry average rejection rate proves the current approach isn't working.

The solution is working smarter. Modern tools can systematically extract requirements from construction specifications, compare them against submittal data, and provide detailed compliance reports in hours instead of days. This technology doesn't replace project managers and engineers - it amplifies their effectiveness, handling tedious data comparison while they focus on judgment, coordination, and problem-solving.

Those who embrace better approaches to specification management gain a competitive advantage: faster projects, higher project quality, better client relationships, and teams that can handle more work without burning out on an existing building renovation or new construction project.

The specifications define what you're building. How you verify compliance determines whether you build it right the first time - or spend weeks in rejection cycles fixing problems that a thorough review would have caught.

Ready to transform how your team reviews submittals against specifications? BuildSync reduces submittal review time by up to 80% while improving compliance verification. See it working on your actual project submittals. Schedule a personalized demo and discover why 70% of pilot teams become customers.

Frequently Asked Questions

What are examples of specifications?

Construction specifications examples include HVAC equipment specifications defining required capacities and efficiencies, concrete specifications detailing mix designs and strength requirements, door and hardware specifications listing acceptable manufacturers and finish requirements, and electrical specifications covering panel schedules and wire sizing. Every technical requirement that defines "what" and "how good" rather than "where" and "how many" is a specification.

Can construction specifications be changed during a project?

What's the difference between specifications and drawings?

Who is responsible for creating construction specifications?

Related reads for you

Discover more articles that align with your interests and keep exploring.