Construction Technology & Innovation

/

Dec 21, 2025

What Is a Submittal in Construction? A Complete Guide to Types, Process & Best Practices

A complete guide to construction submittals: what they are, why they matter, common types, and how to avoid the mistakes that cause 30-40% to get rejected.

Before any major piece of equipment gets installed on a construction project - before that $50,000 air handler gets ordered, before those lighting fixtures ship, before any manufacturer gets a purchase order - there's a critical review process that happens.

It's called the submittal process, and it's the quality control checkpoint that determines whether proposed products actually meet project specifications.

A construction submittal is documentation submitted by a contractor or subcontractor to prove that proposed materials, products, or methods meet project specifications and design intent. It's formal verification in the construction process that ensures the right equipment, with the right specifications, gets installed on your project - not just what the subcontractor wants to provide or what's easiest to procure.

Why this matters: When submittals are done right, projects stay on schedule and equipment installations go smoothly. When they're done wrong, the costs add up fast. Industry data shows that 30-40% of construction submittals get rejected on first submission.

Each rejection pushes your timeline out 2+ weeks, costs approximately $805 in administrative burden, and can trigger cost overruns that threaten project success. Your project team might spend days reviewing product data sheets, trying to verify every technical detail - time that could be spent on higher-value project management.

This guide covers everything you need to know: the different types of construction submittals, the submittal review process, why the system exists, and how to avoid the mistakes that cause rejections and delays.

Because in construction, submittal problems aren't just paperwork headaches - they're schedule killers and budget busters.

What is a Submittal in Construction?

A construction submittal is formal documentation that demonstrates proposed products, different materials, or methods comply with design documents and project requirements. Construction submittals are created by subcontractors, manufacturers, or suppliers and submitted to the general contractor for review and approval. The GC then reviews for compliance before forwarding to the design team (architect and engineers) for final approval through the approval process.

Think of construction submittals as proof before purchase. Before a mechanical subcontractor orders a $50,000 air handler, they submit technical information showing it meets every specification requirement - from BTU capacity to coil coatings to energy efficiency ratings. The design team reviews and either approves it, requires resubmission, or rejects it entirely.

Understanding what submittals are is just the first step. The real challenge is executing an effective review process that catches non-compliance before submission. For a deep dive into review best practices and common pitfalls, see our complete guide to construction submittal reviews.

What Should Be Included in a Construction Submittal?

A construction submittal isn't just a product brochure - it's comprehensive necessary documentation proving compliance with project specifications. Missing key elements is the #1 reason for rejections.

What Every Submittal Should Include

Product Data Sheets: Manufacturer specifications covering all technical characteristics - capacity ratings, dimensions, different materials, performance data, and operating characteristics. For complex equipment like air handlers, expect 40-60 pages of detailed technical information.

Certifications and Approvals: Documentation proving the product meets required standards: UL listings, FM Global approvals, NFPA compliance, and energy efficiency ratings. Without documented proof, the product can't be installed on the construction site. These certifications are critical for ensuring compliance with building codes and structural integrity requirements.

Installation Instructions: Required clearances, mounting requirements, and connection details. Critical for coordination - discovering your mechanical unit needs 36" clearance when drawings show 24" stops construction projects before work begins.

Warranty Information: Must match specification requirements. If specs require a 10-year warranty and your product offers 5 years, it's non-compliant.

Performance Data and Test Reports: For complex systems, include performance curves, test results, energy modeling, and load calculations proving equipment performs as designed.

Why Complete Submittals Matter

Incomplete submittals are automatically rejected. The design team won't guess - they'll reject and request resubmission.

The difference between 5% and 35% rejection rates?

Submittal completeness and organization. Construction teams that invest time in thorough preparation get faster approvals and fewer resubmissions. Getting it right the first time keeps construction projects moving and demonstrates professionalism.

What Are the Different Types of Construction Submittals?

Not all construction submittals are created equal. Understanding the different submittal types helps construction teams allocate review time appropriately and catch issues specific to each category. Many teams address these distinctions during the pre-construction conference to ensure everyone is on the same page.

Type | Purpose | Common Examples | Typical Timeline | Key Requirement |

Product Data | Technical specifications and performance data | HVAC units, lighting fixtures, electrical panels | 2-3 weeks | All technical characteristics verified |

Samples | Visual/physical approval of materials | Flooring, paint, finishes, countertops | 1-2 weeks | Owner approval required |

Mock-ups | Full-scale assembly representation | Wall assemblies, façade sections, restrooms | 2-4 weeks | Quality benchmark for project |

Test Reports | Proof of compliance with standards | Concrete strength, fire resistance, soil tests | 1-2 weeks | Third-party certification |

Certificates | Regulatory compliance documentation | UL listings, FM approvals, NFPA compliance | 1 week | Match specification requirements |

Shop Drawings | Detailed fabrication drawings | Steel connections, ductwork, electrical routing | 3-4 weeks | Coordination critical |

As-Built | Final condition documentation | Updated plans showing all field changes | At closeout | Required for facility management |

Product Data Submittals

A product data submittal is the most common type and typically the most time-consuming to review. These are manufacturer-provided technical specifications, performance data, and installation instructions for equipment and different materials like HVAC units, lighting fixtures, plumbing fixtures, doors, hardware, electrical panels, and building materials.

A single air handler submittal might be 60 pages long with 60+ technical characteristics requiring verification: equipment capacity and ratings, dimensions and clearances, energy efficiency metrics, materials and finishes, controls and accessories, manufacturer approval, and certifications.

Stop spending hours manually checking fixture schedules against plumbing specifications. BuildSync's plumbing submittal review automates the technical analysis of water heaters, backflow preventers, fixtures, and all MEP equipment - freeing up your PMs and plumbing coordinators for higher-value work.

Samples

Physical product samples or material samples are submitted for materials where color, texture, finish, or pattern requires visual approval before installation. These physical examples help ensure compliance with design intent and the requirements outlined in specifications.

Common material samples include flooring materials (carpet, tile, wood, vinyl), paint colours and finishes, brick and masonry units, countertop and millwork materials, fabric and upholstery for furniture, ceiling tiles and acoustical panels, and exterior cladding materials like floor tiles for commercial spaces.

Material samples ensure that what's specified matches what the design team and owner actually want installed - particularly critical for owner-occupied spaces where aesthetics matter as much as performance. This verification process helps keep everyone on the same page before construction starts.

Mock ups

Mockups are full or partial representations of how a system or space will be built on construction projects. Instead of reviewing material samples individually, mockups show how everything comes together, such as a wall assembly, façade section, or restroom layout. They highlight workmanship, detailing, and overall appearance while verifying the structural integrity of assemblies.

Once approved through the submittal process, mockups serve as a benchmark for quality across construction projects. Construction teams use them as a standard to match, and inspectors use them to evaluate completed work. In some cases, mockups remain in place as part of the finished construction.

Test and Inspection Reports

Test and inspection reports provide proof that materials and systems meet required standards and codes as part of the construction submittal process. These reports may come from third-party labs, inspectors, or certified professionals and cover items like concrete strength, soil conditions, fire resistance, or system performance. Submitting these reports helps ensure safety, compliance, and quality control throughout construction projects.

They also create a clear record that required checks were performed and passed, which is important for approvals, inspections, and final sign-off. A responsible contractor maintains comprehensive documentation of all testing throughout the construction process.

Certificates and Warranties

Certificates confirm that products, materials, or systems comply with specific regulations or manufacturer requirements as outlined in the project manual. Examples include compliance certificates, material origin certifications, or installer qualifications. They reassure owners and inspectors that everything was installed correctly and legally per the construction documents.

Common certificate submittals include UL listings for electrical equipment, FM Global approvals for fire protection systems, NFPA compliance certifications, ADA compliance letters, LEED product documentation, and energy efficiency certifications - all critical for ensuring compliance with building codes and regulations.

Shop Drawings

Shop drawings are detailed fabrication and installation drawings created by subcontractors, manufacturers, or fabricators. Unlike generic product data, shop drawings show exactly how a component will be fabricated, assembled, and installed on construction projects using specific materials and methods.

Common shop drawing submittals include structural steel connections and member sizes (critical for structural integrity), mechanical ductwork layouts and equipment connections, electrical panel schedules and conduit routing, architectural millwork and casework details, precast concrete panels and connections, and fire protection system layouts.

As-Built Drawings

As-built drawings show the final condition of construction projects as they were actually constructed. They include changes made during the construction submittal process, such as rerouted utilities, adjusted dimensions, or substituted materials. This makes them more accurate than the original design documents and construction documents. Owners rely on as-built drawings for future renovations, repairs, and facility management.

Having accurate record drawings saves time, reduces guesswork, and helps avoid damaging hidden systems long after project completion. As-built drawing submittals include updated architectural plans showing field changes, mechanical and electrical shop drawings with final routing and connections, structural modifications and reinforcements, site work showing actual utility locations, and fire protection system as-builts for inspection and maintenance.

What is the Purpose of a Submittal?

The primary purpose of submittals is to verify that construction documents, products, and materials specified by the design team will actually be installed on projects.

It's a contractual requirement that serves multiple critical functions and contributes directly to project success.

Quality Assurance

The submittal process ensures products meet project specifications before they're ordered and installed. This catches issues when they're still on paper - not after a $75,000 piece of equipment is sitting on your loading dock or worse, already installed in the building.

Construction research shows that fixing errors during pre-design costs 1/100th of what it costs to fix the same errors during construction. An issue caught on paper might cost $100 to resolve. The same issue discovered after installation? $10,000.

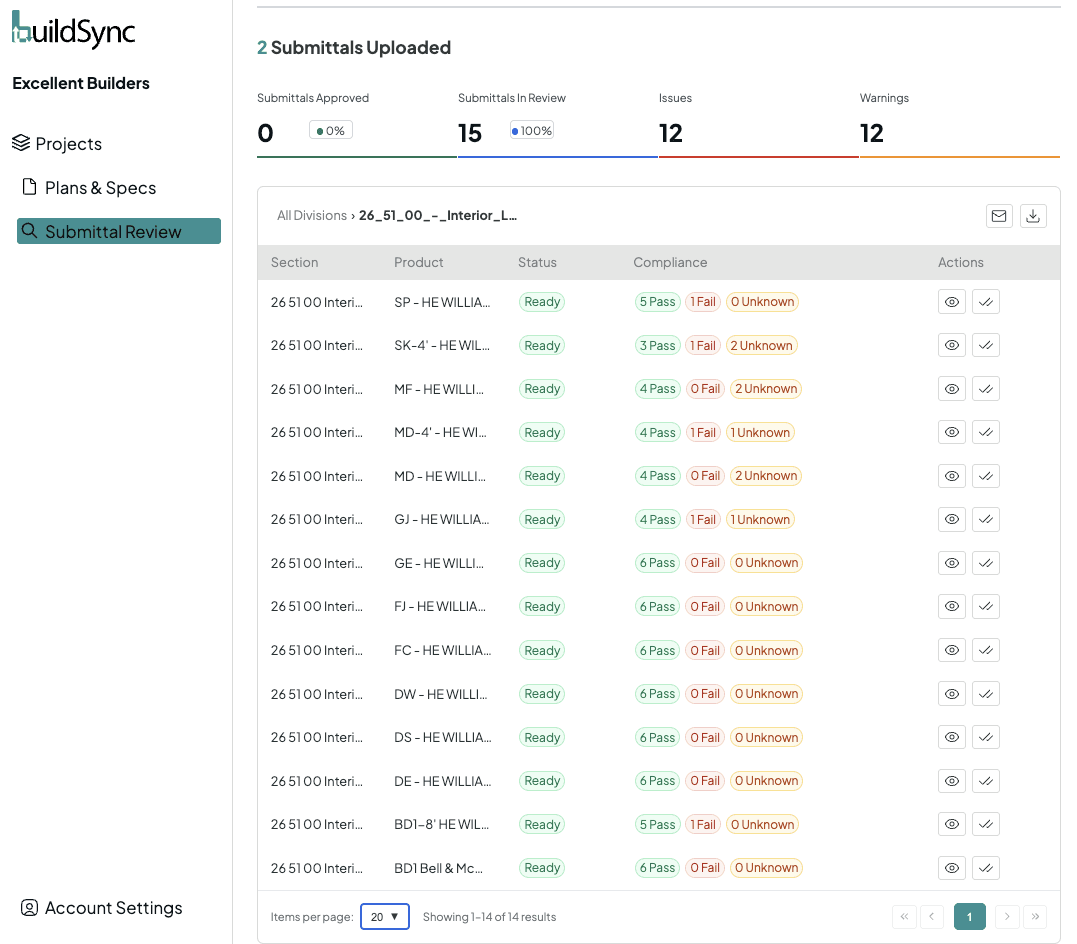

Monteith Construction used BuildSync to help them review submittals to make sure to uncover mistakes early, before they become costly problems:

"BuildSync has helped us review multiple submittals against multiple specs that I would not have thought to reference during my own review process."

Documentation

Approved submittals create a paper trail of what was specified, reviewed, and approved. If there's ever a dispute about whether installed equipment meets contract requirements, the submittal record provides the necessary documentation to resolve it.

This documentation is also critical for warranty claims, commissioning, and facility management after project completion. Modern construction software and digital tools make this documentation easier to manage and retrieve.

Coordination

The submittal process identifies potential issues before they become field problems and threaten structural integrity or system performance. When reviewing an electrical panel submittal, you might catch that the specified breaker doesn't match the mechanical equipment loads.

You might also discover that the specified lighting fixtures won't fit in the ceiling plenum. Finding these coordination issues during the submittal process costs hours of PE time. Finding them during installation costs days of schedule delay and thousands in rework.

Contractual Compliance

Submittals fulfill the contractual obligations between the owner, design team, general contractor, and subcontractors. Project specifications typically include detailed requirements for what must be submitted, when, and in what format.

A responsible contractor adheres to the submittal schedule established during the pre construction conference. Failure to submit proper documentation can delay payment, hold up work, or even be grounds for contract disputes.

Tips for Creating an Effective Construction Submittal Process

Getting construction submittals approved on the first submission requires systematic preparation and attention to detail. Here's what actually works for construction teams using both traditional methods and modern digital tools.

1. Understand the specifications thoroughly

Before you select product samples or prepare submittals, read the entire specification section for your trade in the project manual. Don't just skim for equipment lists - understand the performance requirements, quality standards, and approval process.

Key things to identify:

Required manufacturers (approved lists vs. "or equal" provisions)

Technical performance requirements (capacities, efficiencies, ratings)

Materials and finishes specified, including specific materials and requirements outlined for each trade

Installation requirements that affect product selection

Testing, warranty, and certification requirements

Highlight these project requirements in your copy of the specs. You'll reference them throughout product selection and the submittal process. Understanding these key elements before work begins prevents delays and submittal revision cycles.

2. Organize information clearly

Your submittal reviewer is processing dozens of packages. Make their job easy:

Use submittal cover sheets that list all included products

Create product matrices for multiple similar items (lighting fixtures, VAV boxes, etc.)

Highlight where project specifications are met in manufacturer literature (don't make reviewers hunt)

Include complete data sheets, not just partial pages

Organize submittals by division and specification section

Consider submittal log creation to track all submissions and their status

Proper submittal organization starts with a reliable tracking system that captures all required information from project start to closeout - our construction submittal template provides the framework construction teams need for systematic documentation.

A well-organized submittal signals professionalism and gets faster approval through the approval process. Modern construction software and digital platforms with automated workflows can streamline this organization significantly.

3. Be comprehensive but concise

Include everything required by project specifications - but don't pad the package with irrelevant material data. A 200-page submittal where only 40 pages are relevant frustrates reviewers and increases the chance they'll miss something important.

For equipment submittals, include:

Technical specifications and performance data

Dimensions and clearances

Installation requirements

Certifications and approvals

Warranty information

Operation and maintenance data

4. Double-check before submitting

Before the contractor submits construction submittals:

Verify model numbers match what you're actually proposing

Confirm manufacturers are on the approved list

Check that all project requirements are met and documented

Ensure all required attachments are included

Review for completeness (missing pages are an instant rejection)

Confirm the submittal aligns with the submittal schedule established at the pre construction conference

See how BuildSync automates the construction submittal process and reduces rejection rates.

The Construction Submittal Review Process: How It Actually Works

Understanding the construction submittal review process helps explain why 35% of submittals get rejected and why the process takes so long. For many teams still asking what is a submittal in construction, this workflow shows how documentation moves from subcontractors to the design team - and where delays and rejections most often occur before construction starts.

Here's the step-by-step workflow and what happens at each stage.

Step | Party Responsible | Key Activities | Timeline | Common Issues |

1. Preparation | Subcontractor | Select products, gather manufacturer data, organize documentation | 3-5 days (simple) 1-2 weeks (complex) | Wrong manufacturers, incomplete documentation, missing certifications |

2. GC Review | General Contractor (PM/PE) | Check completeness, verify formatting, catch obvious issues | 2-5 days | Review backlogs, insufficient time for technical review, unclear requirements |

3. Design Review | Architect/Engineer | Verify specifications, check performance, review compliance | 10-14 days (per contract) | Technical non-compliance, coordination issues, substitution pushback |

4. Decision | Design Team | Approve, approve as noted, revise & resubmit, or reject | Varies by outcome | See approval statuses below |

Standard Construction Submittal Process and Workflow

The typical submittal process follows this path:

Subcontractor → General Contractor → Design Team → Back Down the Chain

Each party has specific responsibilities and review timelines. When everything works smoothly, a submittal might take 2-3 weeks to approve submittals.

When it doesn't? You're looking at 6-8 weeks with multiple resubmissions that delay when work begins.

Step 1: Subcontractor Prepares the Submittal

The subcontractor (mechanical, electrical, plumbing, or specialty trade) is responsible for:

Selecting products that meet project specifications

Gathering manufacturer product data sheets with complete technical information

Creating submittal packages with all required documentation

Highlighting where products meet specification requirements

Organizing materials according to specification divisions

Timeline: 3-5 days for straightforward equipment; 1-2 weeks for complex systems with multiple components

Common problems at this stage:

Selecting products that don't match the requirements outlined in the specifications

Incomplete documentation (missing certifications, warranty info, etc.)

Poor organization that makes review and approval difficult

Not verifying the manufacturer is on the approved list

Missing key elements that trigger automatic rejection

Step 2: General Contractor Reviews for Completeness

The GC's project manager or project engineer reviews the submittal before forwarding it to the design team. This is NOT a technical compliance review - that's the design team's job - but rather a check for:

Completeness (all required documents included)

Proper formatting and organization

Obvious issues (wrong manufacturer, missing pages, etc.)

Compliance with submittal requirements in the specifications

Adherence to the submittal schedule established during planning

Timeline: 2-5 days, depending on submittal complexity and PE workload

The reality: This is where construction project submittals often sit for days or weeks. A construction manager juggling 15 other priorities might delay review. A 60-page air handler submittal might sit in the queue behind three other submittals that came in first.

When the construction manager finally reviews it, if they find issues, it goes back to the sub for revision before it ever reaches the design team. Digital tools and construction software can help track and prioritize reviews more efficiently.

Common problems at this stage:

PMs don't have time for a thorough technical review (nor should they - that's the design team's role)

Junior PEs may lack the experience to catch technical issues

Submittals pile up during busy periods (early project phases, procurement deadlines)

Back-and-forth with subs on obvious issues adds days to the timeline

Lack of construction software to streamline review and approval

Delays that push back when construction starts on critical path items

Step 3: Design Team Technical Review

The architect and engineering consultants conduct a detailed technical review to verify:

Product specifications match design requirements

Performance characteristics meet design intent and structural integrity needs

Dimensions and clearances work with building systems

Materials and finishes match the design aesthetic

Required certifications and approvals are included to ensure compliance

Installation methods are acceptable

Timeline: 10-14 days (per contract requirements) but often longer during peak periods

The reality: The design team reviews dozens of submittals across multiple construction projects. They prioritize based on project schedules and their own capacity. A straightforward lighting fixture submittal might get turned around in a week.

A complex mechanical system with 60+ technical characteristics? That's getting detailed scrutiny and taking the full 14 days - or longer if the engineer has questions.

Common problems at this stage:

Design team catches issues the GC review missed

Technical non-compliance that wasn't obvious in manufacturer's literature

Coordination issues between different trades' submittals

Design team pushback on substitutions or "or equal" products

Lack of clarity on whether products meet performance intent

Issues that require additional coordination before work begins

Step 4: Response and Resubmission

The design team typically responds with one of these actions:

Status | Meaning | Next Steps | Timeline Impact |

Approved | Meets all requirements | Proceed to procurement | None - move forward |

Approved as Noted | Acceptable with minor corrections | Implement noted changes | Minimal - clarifications only |

Revise & Resubmit | Non-compliant - corrections needed | Make revisions, resubmit | +2-4 weeks (full cycle) |

Rejected | Does not meet requirements | Select new product, start over | +2-4 weeks minimum |

How to Improve Construction Submittals

Improving construction submittals is about changing your approach to the entire construction submittal process.

The difference between a 35% rejection rate and a 5% rejection rate comes down to systematic technical verification before submission - and modern digital tools are making this easier than ever.

Master the specifications before you select products

Most submittal problems trace back to an incomplete understanding of what the specs actually require. Don't just match model numbers. Verify every performance characteristic, material specification, and certification requirement.

That air handler isn't compliant just because it's the right tonnage. Does it have the specified coil coating? The correct fan motor efficiency? The required control sequence?

Understanding the requirements outlined in specifications prevents costly errors that lead to cost overruns.

Read the entire specification section for your trade. Highlight every technical requirement. Create a checklist of what must be verified. This upfront investment in understanding saves weeks of resubmission time later.

Verify compliance internally before submission

Waiting for the design team to tell you the product doesn't meet specs wastes 2+ weeks and damages credibility. Catch those failures internally, whether through thorough manual review or AI-powered analysis that extracts and verifies every technical detail.

Modern construction software like BuildSync can automate this verification process, providing automated workflows that catch non-compliance before the contractor submits to the design team. This digital platform approach ensures compliance becomes systematic rather than manual.

The most successful contractors treat internal review as if it were the final review. They don't submit anything they haven't thoroughly verified against specifications. This mindset shift alone dramatically reduces rejection rates.

Organize submittals for fast, easy review

The design team processing 50 submittals doesn't have time to hunt through 80 pages for critical specifications. Make their job easy, and you'll get faster approvals.

Best practices for organization:

Use clear cover sheets listing all included products

Highlight where specifications are met in manufacturer literature

Create submittal matrices for multiple similar items

Include only relevant pages - no padding with irrelevant material

Add page references to specific specification sections

Construction teams with the lowest rejection rates treat submittal preparation as technical verification, not administrative paperwork. They invest time upfront to avoid costly resubmissions and schedule delays that threaten project success.

To make sure you keep your projects on track, check out 7 practical ways to improve your submittal review process.

Establish systematic workflows from project start

A responsible contractor establishes clear automated workflows during the pre-construction conference to ensure the entire team stays on the same page throughout the construction process.

Define submittal requirements and review responsibilities early. Create a submittal schedule that accounts for review times and dependencies. Use digital tools to track submittals through the approval process. Set internal deadlines that build in buffer time before construction deadlines.

This systematic approach keeps the whole project moving forward and prevents delays before work begins. Teams that establish these processes early see lower rejection rates and shorter review cycles across all their projects.

Conclusion

Construction submittals are a critical quality control mechanism - but the traditional manual submittal review process is broken. With 30-40% of construction submittals getting rejected and construction teams spending hundreds of hours on reviews, there's a better way through modern digital tools and construction software.

Key takeaways:

Construction submittals verify compliance before products are ordered and installed - catching costly errors on paper instead of in the field

Different submittal types require different review approaches, with product data submittals being the most complex and time-consuming

35% rejection rate is common because manual submittal review misses technical details in complex manufacturer documentation

Each rejection costs 2+ weeks and ~$805 in wasted time and administrative burden, contributing to cost overruns

Effective construction submittals require systematic preparation, attention to detail, and thorough technical verification

AI-powered construction software can reduce rejection rates from 35% to 5% while saving 70-80% of review time

A responsible contractor implements automated workflows on a digital platform to streamline the construction process

Getting construction submittals right the first time saves weeks on your timeline, reduces costs, and frees construction teams to focus on building - not paperwork. Whether you're a subcontractor preparing construction submittals or a GC reviewing them, investing in better processes and digital tools pays immediate returns for project success.

The construction industry is changing. Companies that adopt AI-powered construction submittal process automation now are seeing dramatic improvements in efficiency and accuracy. Construction teams rely on these digital platforms with automated workflows to handle increasing project complexity and schedule demands while ensuring compliance before construction starts.

Before investing in any submittal review technology, check out our guide to the best construction submittal software and test it in real conditions. Upload your most problematic submittals - the ones that usually get rejected - and see what the AI catches. Our pilot guide walks you through exactly how to structure this evaluation.

Book a demo to see the digital platform in action on your actual construction submittals.

FAQs About Construction Submittals

What is an example of a submittal?

An example of a submittal is an air handler product data sheet submitted by a mechanical subcontractor on construction projects. It includes the manufacturer's technical specifications, performance data, dimensions, and required certifications to confirm the equipment meets the project's design requirements.

What is the difference between a submittal and an RFI?

What happens if a submittal is rejected?

Who is responsible for preparing and submitting submittals?

Related reads for you

Discover more articles that align with your interests and keep exploring.