Construction Technology & Innovation

/

Dec 1, 2025

Construction Submittal Review Process: Complete Guide (2026)

Master the construction submittal review process with our comprehensive guide. Learn requirements, best practices, compliance checks, and how to avoid costly rejections.

Let's talk about something the construction industry has quietly normalized: a 35% submittal rejection rate.

If 35% of your concrete pours failed inspection, you'd have a crisis. If 35% of your change orders were disputed, you'd investigate immediately. But when 35% of project submittals get rejected on first review? That's just Tuesday.

Why has this been tolerated? Because until recently, there was no alternative. Manual submittal review - extracting data from 70-page cut sheets, cross-referencing against 200-page specifications - was the only option. And it didn't scale.

That just changed. Here's how the best construction teams are eliminating submittal review as a bottleneck.

In this guide, you'll get:

The hard numbers on what submittal rejections actually cost you on most construction projects (spoiler: $140,000+ per 500-submittal project)

Where the submittal process breaks down - and exactly how to fix each bottleneck

Five proven strategies that consistently drive rejection rates from 35% down to under 5%

How forward-thinking teams are using AI to scale review capacity without adding headcount

You already know submittals are painful. Let's fix it.

What Is Construction Submittal Review?

Construction submittal review is the quality control process that verifies proposed materials, equipment, and products meet code and project requirements, and owner expectations before installation.

The process involves multiple parties: subcontractors prepare submittal documents, vendors supply product data, general contractors conduct preliminary reviews, and design teams (architects and engineers) provide final technical approval before procurement.

Currently, industry averages show that 35% of submittals get rejected on first review, costing $805 per rejection and adding 2-4 weeks to project timelines. For a typical 500-submittal project, that's $140,000 in preventable costs and 525 weeks of cumulative delays across all submittals.

The Real Cost of Getting The Reviews Wrong: Example

Consider a rooftop HVAC unit submittal for a hospital construction project. The specifications call for R-454B refrigerant. The submitted unit uses R-410A. It's a single line item buried in a 70-page cut sheet - easy to miss when you're rushing through your twentieth submittal of the week. But if installed, it could violate a warranty.

The unit must be returned. A compliant unit must be ordered - 16-20 week lead time. Installation gets delayed, the construction schedule is affected, and project efficiency tanks. Downstream mechanical trades get impacted.

Total cost: $75,000-$150,000. Time lost: 4-6 months. All because one specification wasn't caught during review.

Once equipment or materials are installed, replacing non-compliant work costs 50-100 times more than catching issues on paper.

What Submittal Review Ensures

Construction submittal review verifies six critical aspects before installation:

Verification Area | What Gets Checked |

Code Compliance | Building codes, energy codes, fire codes, accessibility codes, electrical codes |

Design Intent Maintained | Aesthetic, functional, and performance requirements match what was designed |

Product Quality Standards | Materials, durability, and specifications meet contract requirements |

Proper Certifications | UL, AHRI, ASME, ETL, NSF, DLC, Energy Star, and required testing documentation |

System Coordination | Physical dimensions, clearances, connections, and integration with other building systems verified |

Project Documentation | Complete information for as-built records, O&M manuals, and building operations |

How to Review Submittals: Step by Step

The submittal process follows six steps:

Submittal preparation by subcontractor (often in coordination with vendors who supply product data)

GC preliminary review

Submission to the design team

Design team technical review

Response and revisions if needed

Final approval and procurement

Step 1: Submittal Package Preparation (Subcontractor/Vendor)

What happens: Subcontractors gather manufacturer product data, cut sheets, technical specifications, certifications, and test reports. They mark up cut sheets to highlight specific products for specific locations, prepare submittal transmittal forms with project information, and ideally create compliance matrices showing how products meet specifications.

Who's responsible: Specialty contractors - MEP, electrical, plumbing, fire protection

Timeline: 2-5 days for standard equipment; 1-2 weeks for complex custom items

Common issues that cause problems later:

Incomplete information (missing certifications, unmarked cut sheets)

Wrong products selected that don't match specs

Generic manufacturer literature not tailored to the project

Missing equipment tags or location references

No documentation showing specification compliance

Documents required:

Manufacturer cut sheets and technical data

Certifications (UL, AHRI, ASME, ETL, DLC, etc.)

Test reports and performance data

Material safety data sheets (if required)

Warranty information

Installation and O&M manuals

Step 2: GC Preliminary Review (General Contractor)

What happens: The Project Engineer or construction manager reviews the submittal for completeness, checks for basic compliance with specifications, verifies correct products for correct locations, checks coordination with other trades, and adds GC review stamp and notes before transmitting to the design team.

Who's responsible: PM or PE at the general contractor

Timeline: 1-5 business days (but often longer when teams are overwhelmed)

Manual effort: 4-8 hours per complex submittal, like MEP equipment

The challenge: This is where most manual review time gets spent. During the initial review, PEs are cross-referencing 70-page manufacturer cut sheets against 30-50 page specifications from the project manual. It's tedious, detail-intensive work requiring technical knowledge across multiple disciplines. When teams are overwhelmed with volume - which is common during the first six months of a project - this step often gets rushed.

Tom Port, the co-founder of BuildSync, says:

The biggest bottleneck we see is usually between the GC review and the design team submission — when GCs realize the product data doesn’t fully match the specs, but don’t have the time to dig through hundreds of technical characteristics. That’s where submittals stall.

Critical importance: The GC review is the first line of defense. A thorough review here catches issues before they reach the design team, avoiding the costly 2-4 week rejection cycle. This is the most impactful place to improve your process, ensuring that the construction project progresses smoothly.

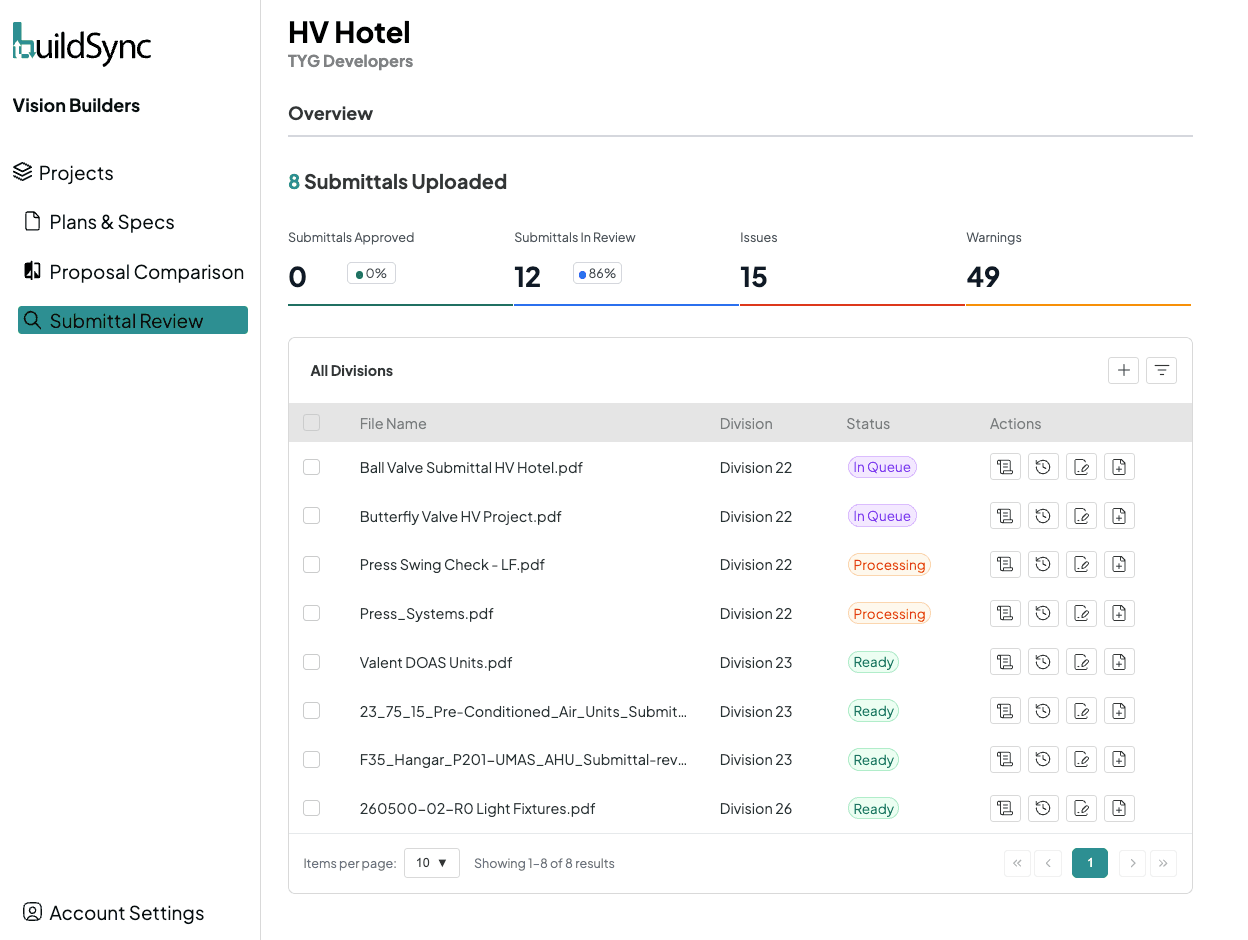

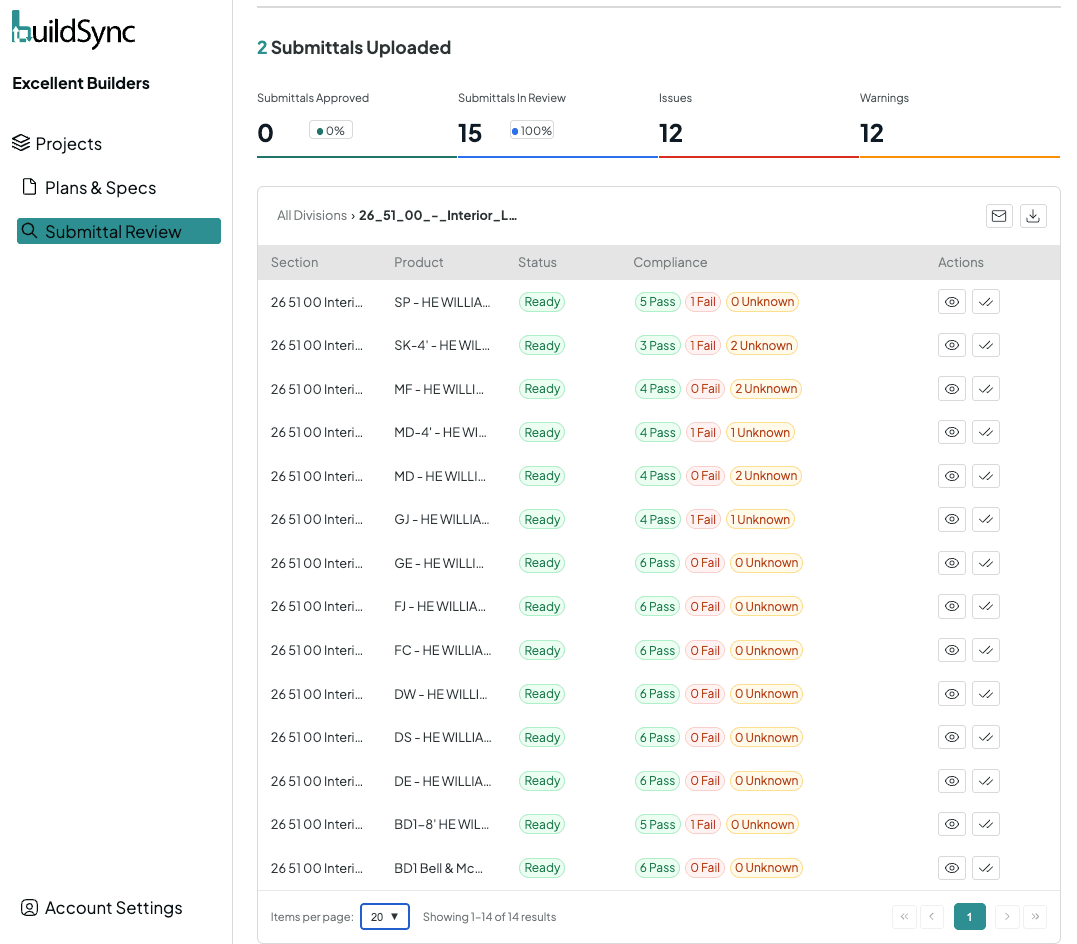

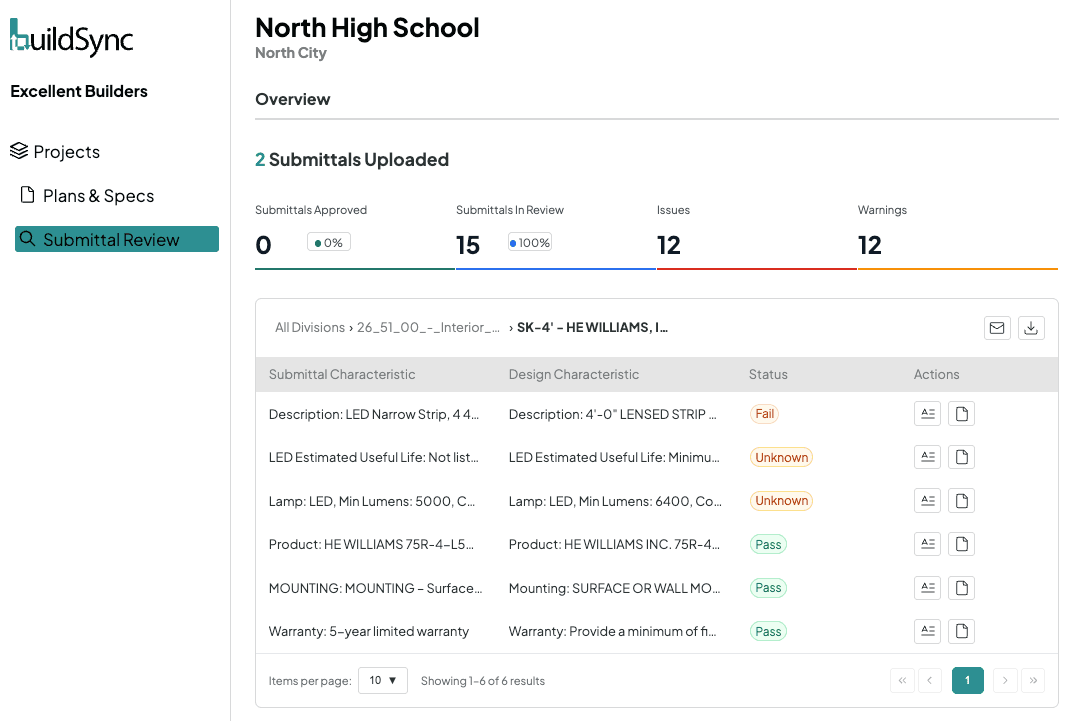

Caption: BuildSync Submittal Review Tab

Step 3: Submission to Design Team

What happens: The GC formally transmits the submittal to the architect or engineer of record, usually through project management software like Procore. The submittal package includes the original submittal with GC markups, any compliance matrices, GC review notes and questions, and a transmittal form with project details.

Who's responsible: GC project team

Timeline: 1 day (administrative processing)

Critical moment: This is the gate. From here, the submittal either gets approved or comes back rejected, sending you back to square one.

Step 4: Design Team Technical Review

What happens: The architect or engineer performs detailed technical analysis, reviewing against contract documents (both drawings and specifications), checking code compliance, verifying design intent is maintained, reviewing any substitutions or "or equal" products, and checking coordination with overall building systems.

Who's responsible: Different specialists review different submittals:

Architect: Architectural submittals (finishes, doors, glazing, roofing)

Structural Engineer: Structural submittals (steel, concrete, connections)

MEP Engineers: Mechanical, electrical, plumbing equipment submittals

Fire Protection Engineer: Fire alarm and sprinkler system submittals

Timeline: 2-4 weeks typical (can extend to 4-6 weeks when they're backlogged)

What they're checking:

Complete compliance with every specification requirement

Code compliance (IBC, ASHRAE, NFPA, NEC, local codes)

Design intent alignment

Product equivalency (if substitution proposed)

Performance requirements met

Proper certifications included

Warranty terms acceptable

Adequate O&M documentation

Their authority: Design teams have final say on all technical matters. If they reject it, it doesn't get installed - period.

Their challenge: Overworked and backlogged. Large projects generate 1,000-2,000 submittals. Design teams are often reviewing submittals for 10+ projects simultaneously. Your submittal is in a queue competing for attention.

Step 5: Response & Potential Revisions

Design team response options:

Response | Meaning | Timeline Impact |

Approved | Product meets specifications - proceed with procurement and installation | ✓ No delay |

Approved with Exceptions | Minor issues noted, but can proceed with documented modifications | ✓ Minimal delay |

Revise and Resubmit | Non-compliance issues identified - must be corrected and resubmitted | ⚠ 2-4 week delay - back to Step 1 |

Rejected | Major non-compliance, wrong product, or unacceptable substitution | ⚠ 2-4+ week delay - full resubmission |

No Exceptions Taken | Design team declines to review the proposed substitution | ⚠ Must resubmit specified product |

Impact of "Revise and Resubmit": When a submittal comes back needing revision, the entire process starts over. The subcontractor must coordinate with the manufacturer, revise the submittal, resubmit to the GC, the GC re-reviews, resubmits to the design team, and the design team re-reviews. This adds weeks to the review cycle - often longer if the issue requires significant product changes or manufacturer coordination.

Step 6: Final Approval & Procurement

What happens: The GC receives the approved submittal from the design team and forwards approval to the subcontractor. The subcontractor can now issue a purchase order to the manufacturer. The approved submittal becomes part of the permanent project record. Equipment or materials can be fabricated and delivered. Installation can proceed per the approved documents.

Delays in submittal approval directly impact these lead times, proposed timeline, and potentially the entire project schedule.

Documentation: Approved submittals become the basis for as-built documentation, reference for warranty claims, part of O&M manual compilation, and the official record of what's actually installed.

This is where AI-powered submittal review transforms the process.

BuildSync performs that detailed Step 2 GC review in hours instead of days - extracting technical characteristics from submittals and comparing them against project specifications before anything reaches the design team.

What Are the Different Types of Construction Submittals?

There are three main types of construction submittals:

Product data submittals - manufacturer specifications and technical data (70% of submittals)

Shop drawings - detailed fabrication and installation drawings (20% of submittals)

Samples - physical material samples for visual approval (10% of submittals).

Product data submittals are most common and typically require a detailed technical specification review.

1. Product Data Submittals (70% of all submittals)

What they are: Manufacturer specifications, cut sheets, technical data sheets, performance reports, test results, and certifications for equipment and materials.

Most common examples:

Trade | Typical Product Data Submittals |

HVAC Equipment | Rooftop units, chillers, boilers, air handlers, exhaust fans |

Electrical Equipment | Lighting fixtures, panelboards, transformers, switchgear, generators |

Plumbing Equipment | Water heaters, pumps, fixtures, backflow preventers |

Fire Protection | Sprinkler heads, fire pumps, fire alarm devices, smoke detectors |

What gets reviewed: Technical specifications match contract documents exactly, capacity and performance ratings, physical dimensions and weights, materials and finishes, electrical requirements, required certifications, energy code compliance, sound and vibration ratings, warranty terms, installation and O&M documentation.

Review complexity: High - requires systematically checking dozens of technical specifications against contract documents.

BuildSync specialization: This is exactly what BuildSync excels at - deep technical analysis of product data submittals. BuildSync extracts all technical characteristics from manufacturer cut sheets and systematically compares them against project specifications.

2. Shop Drawings (20% of submittals)

What they are: Detailed fabrication and installation drawings showing exactly how something will be built, including precise dimensions, connection details, materials specifications, and coordination with other building systems.

Common examples:

Trade | Shop Drawing Examples |

Structural Steel | Connection details, erection sequences, anchor bolt layouts |

Mechanical/HVAC | Ductwork layouts, equipment placement, piping coordination |

Fire Protection | Sprinkler system layouts, head locations, hydraulic calculations |

Architectural | Custom millwork shop drawings, curtain wall panel details |

Precast Concrete | Panel elevations, connection details, embedment locations |

Review complexity: Very high - requires dimensional verification, structural engineering analysis, spatial coordination review.

3. Samples (10% of submittals)

What they are: Physical examples of materials submitted for visual inspection, tactile evaluation, and quality approval before full-scale procurement.

Common examples:

Trade | Physical Sample Examples |

Flooring | Carpet, tile, hardwood, vinyl, terrazzo |

Paint & Coatings | Paint colors, stains, sealers, wall finishes |

Casework & Millwork | Cabinet door samples, countertop materials, hardware finishes |

Masonry | Brick, CMU, stone veneer units |

Ceilings | Acoustic ceiling tiles, panel finishes |

Furnishings | Fabric swatches, upholstery samples, panel fabrics |

Review complexity: Lower technical specification complexity, higher emphasis on aesthetic judgment and owner preferences.

Typical large commercial project distribution:

Product data submittals: 450-650 submittals (~60-70%)

Shop drawings: 150-250 submittals (~20-25%)

Samples, mockups, and misc: 50-120 submittals (~10-15%)

Total typical range: 650-1,000 submittals

The heaviest concentration hits during months 2-7 of construction, creating significant workload pressure on project teams.

What Should I Look for When Reviewing Submittals?

Different project stakeholders review submittals with different priorities and authority levels. Here's what each role should focus on during their review and approval process to ensure compliance with project requirements.

Project Manager: Schedule, Coordination & Completeness

Primary Focus: Keeping the construction project on schedule and ensuring all necessary documentation is complete before it reaches the design team.

What to check:

Completeness of submittal package: All required items included - cut sheets, certifications, test reports, warranty information, O&M manuals

Proper product identification: Equipment tags and location references match project detailed drawings and schedules

Schedule compliance: Lead times align with project schedule; flag long-lead items requiring expedited review

Coordination across trades: Physical dimensions and clearances verified; no conflicts with other systems

Substitution documentation: If proposing "or equal" products, equivalency documentation is thorough and complete

Subcontractor performance tracking: Which subs consistently submit quality work vs. incomplete packages

Common issues PMs catch:

Missing equipment tags or unclear location references

Incomplete certification packages that will get kicked back

Products that don't coordinate with adjacent systems

Submittal packages that will obviously fail design review

PM Authority Level: Administrative review and coordination verification; cannot approve technical compliance (that's the design team's role)

Time investment with traditional manual review: 2-4 hours per complex submittal package

Why this matters: The PM's review is the gatekeeper. A thorough review here prevents wasting the design team's time with incomplete or obviously non-compliant submittals - and avoids the costly 2-4 week rejection cycle.

Architect or Engineer: Technical Compliance & Design Intent

Primary Focus: Verifying proposed materials and equipment meet all technical requirements, code compliance, and project's design intent before authorizing procurement and installation.

What to check:

Review Category | Architect Focus | Engineer Focus (MEP) |

Aesthetics & Design | Materials, finishes, colors match design intent | Equipment appearance and integration |

Performance | Durability, maintenance requirements, warranty terms | Capacity, efficiency ratings, operational parameters |

Code Compliance | Building code, accessibility, fire code | Energy code, mechanical code, electrical code, plumbing code |

Technical Specs | Material specifications, installation details | Exact technical match: refrigerant types, electrical requirements, efficiency ratings |

Coordination | Anchoring, flashing, weatherproofing, building envelope integration | Dimensions, weights, clearances, access requirements, physical fit |

Systems Integration | Overall building aesthetics and functionality | Control system compatibility, building automation integration |

Certifications | General product certifications | AHRI, ASME, UL, ETL, NSF, DLC, Energy Star |

Sustainability | LEED credits, embodied carbon, recycled content | Energy efficiency, environmental compliance |

Substitutions | "Or equal" equivalency verification | Performance and technical equivalency |

Structural | General installation requirements | Seismic requirements, anchorage, bracing, support details |

Common issues design teams catch:

Wrong refrigerant type (code violation)

Insufficient efficiency ratings (energy code non-compliance)

Missing required certifications

Products that don't match specifications

Inadequate performance data to verify compliance

Substitutions that don't actually meet "or equal" criteria

Design Team Authority Level: Final technical authority - if they reject it, it doesn't get installed, period.

Timeline: 2-4 weeks typical for design team review (can extend to 4-6 weeks when backlogged)

Why this matters: Design teams are often reviewing project submittals for 10+ projects simultaneously. Your submittal is competing for attention. The more complete and obviously compliant it is, the faster it moves through their queue.

General Contractor: First Line of Defense

Primary Focus: Conduct a thorough preliminary review to catch issues before they reach the design team, ensuring the entire process moves efficiently without costly rejections and resubmissions.

What to check in your preliminary review:

Review Area | What to Verify |

Basic Specification Compliance | Does the proposed equipment generally match what's specified? |

Completeness Verification | All required documentation included before transmitting to design team |

Equipment Schedule Alignment | Correct products tagged for correct locations |

Obvious Non-Compliance Issues | Wrong product types, missing major requirements, clear spec violations |

Coordination Red Flags | Dimensional conflicts, clearance issues, access problems |

Substitution Quality | If sub is proposing "or equal," is the documentation thorough enough for design team review? |

Critical items that commonly get missed (and shouldn't):

Specific refrigerant types in HVAC equipment (R-410A vs. R-454B)

Light transmittance percentages in glazing (affects daylighting, energy code)

Coil coating specifications for corrosive environments

Sound ratings in dB for occupied spaces (noise ordinance compliance)

Minimum efficiency ratings (EER, SEER, thermal efficiency)

Control system protocol compatibility (BACnet vs. proprietary)

Spare parts and attic stock requirements for closeout

GC Authority Level: Preliminary review and coordination verification; final technical approval rests with design team

Time investment with manual review: 4-8 hours per complex submittal for thorough review

The reality: When project teams are overwhelmed with volume during peak periods (months 2-7 of a construction project), this step often gets rushed or rubber-stamped. That's when rejection rates spike to 40-50%.

This is where AI-powered submittal review transforms the process. BuildSync performs that detailed Step 2 GC review in hours instead of days - extracting technical characteristics from submittals and comparing them against project specifications before anything reaches the design team.

Subcontractors and Suppliers: Quality Control Before Submission

Primary Focus: Submit complete, compliant submittal documents the first time to avoid rejections, schedule delays, and relationship damage with the GC and design team.

What to verify before submitting:

Documentation Type | Required Content |

Product Identification | Equipment tags match project drawings and schedules exactly |

Technical Specifications | All performance specifications, ratings, dimensions clearly shown |

Manufacturer Data | Specific products highlighted on marked-up cut sheets; not generic catalogs |

Compliance Certifications | UL, AHRI, ASME, ETL, NSF, DLC listings as required by specifications |

Performance Documentation | Energy efficiency ratings, sound ratings, seismic certifications, test reports |

Warranty Information | Terms meet or exceed specification requirements |

Operational Documentation | Complete installation and O&M manuals for contractor and owner use |

Common mistakes that cause rejections:

Unmarked manufacturer catalogs (no indication of which product applies where)

Missing certifications or test reports

Products that don't meet specifications (wrong capacity, efficiency, or features)

Incomplete information requiring RFI for clarification

Poor organization making it difficult to review

Why this matters: Every rejection adds multi-week delays to YOUR timeline, delays your installation work, and damages your reputation. Submitting quality work the first time keeps you on schedule and builds trust.

Best practice: Review your own submittal package before submission. Check it against specifications yourself. If you find issues, fix them before the GC sees them. Your goal is zero rejections.

Project Owner or Client: Protecting Your Investment

Primary Focus: Ensuring you get what you paid for - that proposed materials and systems meet the project manual requirements, design intent, and long-term operational needs.

What the project owner should verify (often delegated to owner's representative):

Impact Area | Owner Verification |

Design & Quality | Aesthetics, functionality, quality level match what was designed and contracted |

Operations & Maintenance | Systems maintainable by facilities team |

Performance Guarantees | Equipment efficiency ratings support guaranteed energy targets |

Risk Management | Warranty length, coverage, and exclusions meet standards |

Common owner concerns:

Substitutions that reduce quality or long-term value ("or equal" that really isn't)

Equipment that's difficult or expensive for their facilities team to maintain

Products that won't integrate with existing building systems

Insufficient warranty coverage for critical systems

Energy performance that doesn't meet operational budget projections

Owner Authority Level: Varies by contract structure; often provides input through design team rather than direct submittal approval

Why this matters: Once construction begins and equipment is installed, changes are exponentially more expensive. Submittal review is your opportunity to ensure you're getting exactly what you paid for before it's built into the building.

Best practice: Don't rubber-stamp every submittal the design team approves. Review key systems that affect your operations - HVAC systems, building automation, critical equipment, major finishes. Ask questions if something doesn't align with your operational needs or expectations.

Common Construction Submittal Review Challenges & Solutions

Even experienced construction teams struggle with submittal reviews. Here are the five most common challenges and practical solutions to address them.

Challenge #1: High Rejection Rates (35% Industry Average)

The problem: As Construction Yeti's Matt Graves puts it:

“30 - 40% of submittals come back rejected (industry average). Not because your team is careless...but because the system is broken.”

Why it happens:

Incomplete submittals from subcontractors (missing certifications, unmarked cut sheets)

Non-compliant products specified that don't meet technical specifications

Inadequate GC preliminary reviews rushed due to time pressure

Knowledge gaps - junior project engineers reviewing complex equipment without sufficient expertise

Poor substitution documentation for "or equal" products

The impact:

Direct cost: $805 per rejected submittal in administrative burden

Timeline impact: Each rejection adds multiple weeks to the cycle

Schedule compression: Cascading delays affect downstream trades

Strained relationships: Repeated rejections frustrate design teams

Increased project risk: Schedule delays increase liquidated damages exposure

The solution: Thorough GC preliminary review is absolutely critical - it serves as the first line of defense. Catching issues before they reach the design team prevents that costly rejection cycle.

Related: 7 Ways To Improve Your Construction Submittal Review Process

Forward-thinking teams are solving this with automated technical review - systematically checking every requirement before submittals reach the design team. BuildSync helps teams drive rejection rates below 5%.

Challenge #2: Time Drain on Project Teams

The reality: Project Engineers commonly spend 20+ hours per week reviewing submittals manually. That's time taken away from coordination, RFIs, jobsite oversight, problem-solving, and all the other critical work PEs should be doing.

This contributes to the industry-wide labor shortage - 77% of firms can't fill positions. You can't afford to waste the PEs you have on tedious data extraction.

Why manual review is so inefficient:

Data extraction is tedious - hunting through 70-page manufacturer cut sheets for specific values

Cross-referencing is time-consuming - page-by-page comparison against 30-50 page specifications

No systematic approach - success relies entirely on reviewer's knowledge and attention to detail

Easy to miss critical details - one overlooked specification = rejection

Doesn't scale - large projects with 1,000+ submittals overwhelm even large teams

The impact:

Review bottlenecks: Submittals pile up during peak periods

Delayed approvals: Procurement delayed, equipment lead times extended

Higher-value work suffers: Less time for proactive coordination

PE burnout and turnover: Tedious work drives people out of the industry

Quality compromises: When overwhelmed, even good engineers rush reviews

The solution: Automate the technical heavy-lifting. BuildSync handles systematic data extraction and specification comparison, saving teams up to three-quarters of time otherwise spent on manual review.

Calculate your savings with BuildSync with our ROI calcuator.

Challenge #3: Technical Complexity & Knowledge Gaps

The problem: Junior project engineers are often expected to review highly complex MEP equipment in their first year on the job. They may not know which specifications are absolutely critical, which are negotiable, and what details are commonly overlooked.

Real examples of specifications that commonly get missed:

Light transmittance percentages in glazing specifications (affects daylighting calculations)

Specific refrigerant types for HVAC equipment (R-410A vs. R-454B - code compliance issue)

Coil coating specifications for equipment in corrosive environments

Sound ratings in dB for equipment in occupied spaces (noise ordinance compliance)

Specific manufacturer certifications required (ASME H-stamp for pressure vessels)

Minimum efficiency ratings buried in text (EER, SEER values)

Control system protocol compatibility (BACnet vs. LonWorks)

The impact:

Non-compliant equipment gets approved and installed based on incomplete review

Issues discovered during commissioning, inspection, or years later during operation

Expensive replacement required after installation (50-100x more costly than catching during review)

Significant schedule delays while replacement equipment is procured

Potential legal exposure and professional liability

Loss of credibility with design teams and subcontractors

The solution: Implement systematic review approaches that check EVERY requirement regardless of reviewer experience level.

Tom Port, BuildSync Co-founder:

We once caught a major non-compliance in an air-handling unit submittal that had already passed the GC and design review.

The unit didn’t meet the specified MERV rating, which would have failed commissioning and delayed occupancy. BuildSync surfaced the exact spec conflict automatically. Often these issues can slip through in a traditional manual review process.

Caption: BuildSync Submittal Review Product breakdown

Systematic review approaches eliminate the knowledge gap problem. BuildSync knows exactly what to check in specifications and where to find it in submittals - checking every requirement regardless of reviewer experience level.

Challenge #4: Incomplete or Poor-Quality Submittals from Subcontractors

Common issues:

Issue | What It Looks Like |

Unmarked Cut Sheets | No indication of which product applies where |

Missing Compliance Documentation | Certifications, test reports, performance data not included |

Generic Submittals | Standard manufacturer catalogs rather than project-specific documentation |

Incomplete Information | Missing critical data needed to verify compliance |

Poor Organization | Submittals difficult to review |

The impact:

RFIs back to subcontractor requesting clarification

Resubmissions and associated delays in approval timeline

Design team frustration with inadequate documentation

Incomplete project closeout documentation

The solution:

Use AI to generate complete, project-specific submittal packages automatically (BuildSync's submittal package generation pulls exactly what's needed from manufacturer data and project specifications - eliminating unmarked cut sheets and missing documentation)

Conduct pre-construction submittal meeting establishing crystal-clear requirements

Provide submittal checklist template to subcontractors

Conduct thorough GC preliminary review to catch incomplete submittals before they waste design team's time

Track subcontractor performance and provide specific, actionable feedback

Challenge #5: Volume Overwhelm During Peak Periods

The reality: Large commercial projects generate 1,000-2,000 submittals, with the vast majority hitting during the early project phase (first 3-6 months). Project Engineer bandwidth simply cannot keep up with this volume using manual review processes.

The compounding problem - a vicious cycle:

High volume forces rushed reviews

Rushed reviews miss issues → Higher rejection rates

Higher rejections → More resubmissions

More resubmissions → Even higher volume

Higher volume → Even more rushed reviews

The impact:

Quality inevitably suffers when teams are overwhelmed

Some submittals get rubber-stamped to clear the backlog

Critical approvals delayed because everything is stuck in the queue

Team morale suffers under unsustainable workload

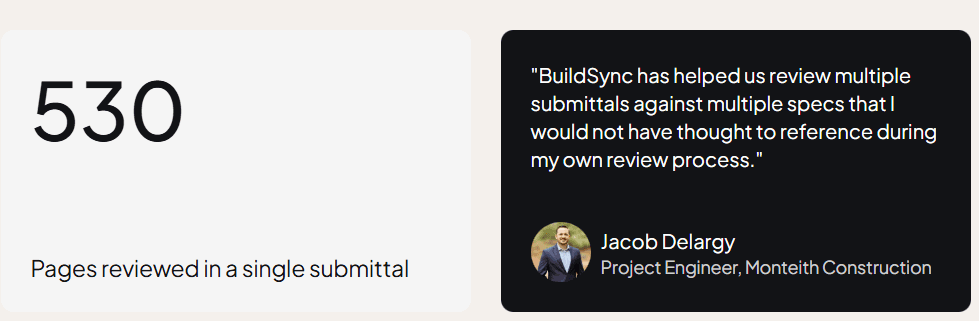

Real-world example: Monteith Construction faced exactly this problem - a small team managing a massive submittal log on complex commercial projects. Their solution was integrating BuildSync as the first checkpoint in their workflow:

BuildSync is the first stop a submittal makes in our workflow once it is turned in by a subcontractor. The report and markup generated by BuildSync then helps our reviewer navigate through the submittal as they perform their own review prior to sending the submittal off to the architect and engineer.

The results were immediate and measurable. On a particularly challenging 530-page A/V submittal - the kind that would normally consume days of PE time - BuildSync processed it systematically while the team focused on coordination and higher-level review.

We have seen an improvement in our review times and acceptance rates. BuildSync's ability to review product data submittals has allowed us to focus more attention and energy to larger submittals and shop drawings.

Perhaps most importantly, BuildSync caught specification cross-references that the team wouldn't have thought to check manually:

BuildSync has helped us review multiple submittals against multiple specs that I would not have thought to reference during my own review process.

How Much Does a Submittal Rejection Cost? The Real ROI Analysis

Let's do the math you haven't done yet.

Each rejected construction submittal costs an average of $805 in direct costs (administrative burden, coordination time) plus indirect costs of 2-4 weeks added to the timeline. For a mid-sized project with 500 submittals and typical 35% rejection rate, total rejection costs exceed $140,000 annually, plus schedule impacts that can lead to liquidated damages.

Breaking Down the Cost per Rejection

Direct costs per rejection ($805 average):

PM/PE time coordinating resubmission: 4-6 hours

Subcontractor time revising and resubmitting: 6-8 hours

Design team time conducting re-review: 2-4 hours

Administrative processing and documentation: 2-3 hours

Communication overhead (meetings, emails, calls)

Indirect costs (harder to quantify but often more significant):

Timeline delay: 2-4 weeks per rejection cycle

Schedule compression affecting downstream trades

Procurement delays and potential expediting fees

Potential overtime costs from compressed schedules

Relationship strain with design teams

Risk escalation toward liquidated damages

Tom Port, BuildSync Co-founder:

We regularly hear from clients that BuildSync has reduced their submittal review cycles from weeks to hours. That speed really matters, because design teams often hold procurement until reviews are complete, and any delay there can cascade across the schedule. It’s incredibly rewarding when customers tell us that BuildSync is the reason their deadlines didn’t slip.

Real Project Cost Analysis

Mid-Sized Commercial Project Parameters:

Total submittals: 500

Industry average rejection rate: 35%

Rejected submittals: 175 (35% of 500)

Baseline costs with 35% rejection rate:

Direct costs: 175 rejections × $805 = $140,875

Average timeline delay per rejection: 3 weeks

Total cumulative delay impact: 525 weeks of delays across all submittals

With rejection rate reduced to 5% using BuildSync:

Rejected submittals: 25 (5% of 500)

Direct costs: 25 rejections × $805 = $20,125

Direct cost savings: $120,750

Timeline impacts reduced by 86%

Additional ROI from Time Savings

Time investment analysis:

500 submittals × 5 hours average manual review time = 2,500 hours total

With time savings from BuildSync: 1,875-2,000 hours saved

At PE burdened rate of $75/hour: $140,625-$150,000 in labor cost savings

Total Annual Project Savings: $260,000-$270,000

This doesn't account for the value of redirecting that PE time to proactive coordination, constructability reviews, value engineering, problem-solving, or mentoring - all higher-value activities than tedious data extraction.

The Hidden Costs

PE Burnout and Turnover: When project engineers spend 50-60% of their time on tedious manual submittal review, burnout is inevitable. Replacing a burned-out PE costs $50,000-$75,000 in recruitment, onboarding, and lost productivity.

Schedule Liquidated Damages Risk: If submittal-related delays push the project past substantial completion date, liquidated damages can be $2,000-$10,000 per day on commercial projects. Even a few critical rejections can trigger six-figure exposure.

Best Practices for Effective Construction Submittal Reviews

Implement these five proven strategies to improve your submittal review process, reduce rejection rates, and reclaim time for higher-value work.

1. Start Early and Prioritize Ruthlessly

Submit early packages immediately after contract award. Prioritize long-lead items that have substantial manufacturing timelines: chillers, generators, elevators, custom switchgear. Don't wait for design team formal requests. Build minimum 2-3 week schedule buffer for potential rejections.

Critical path items requiring immediate attention:

Chillers: 20-26 weeks lead time

Generators: 24-32 weeks lead time

Custom air handlers: 14-18 weeks lead time

Elevators: 20-26 weeks lead time

Switchgear: 26-40 weeks lead time

Why it matters: Long-lead equipment has manufacturing lead times of 20-40 weeks. Every week of submittal approval delay compounds directly into schedule risk. Prioritize critical path items first, then batch similar submittals together (all lighting at once, all HVAC equipment together) for review efficiency.

2. Establish Crystal-Clear Submittal Requirements at Pre-Construction

Conduct a dedicated submittal review meeting during the pre-construction phase. Define precisely what documentation is required: marked cut sheets, compliance matrices, and specific certifications. Explain substitution procedures and equivalency documentation requirements clearly. Provide a submittal checklist template to all subcontractors. Clarify review timelines, responsibilities, and quality assurance protocols.

Why it matters: Clear expectations up front dramatically reduce incomplete submittals and associated rejection rates. Subcontractors know exactly what's required for approval - you are on the same page. Maintain a comprehensive submittal log in your project management softwar,e tracking status, dates, and identifying which subcontractors consistently submit quality work.

3. Conduct Thorough GC Preliminary Reviews (Most Critical Step)

Actually review submittals thoroughly - don't rubber-stamp them. Check for complete documentation before submitting to design team. Verify basic specification compliance systematically. Catch obvious issues early in the process. Use equipment-specific checklists to ensure consistency. Document detailed review notes for design team reference.

Why it matters: Thorough GC review catches issues before they reach the design team, completely eliminating the rejection cycle. This single step delivers the highest return on investment for process improvement.

Time investment comparison:

Manual thorough review: 4-8 hours per complex submittal

With BuildSync automated review: 30-60 minutes reviewing AI-generated comprehensive findings and making final determinations

4. Create Equipment-Specific Review Checklists

Develop detailed checklists for each common equipment type your projects encounter. List project-specific requirements extracted directly from YOUR specifications (not generic checklists). Include common rejection reasons discovered on past projects for that equipment type. Reference exact specification section numbers for each requirement.

Checklist examples:

RTU Checklist: Capacity, efficiency ratings, refrigerant type, electrical specifications, physical dimensions, sound ratings, coil coatings, control system compatibility, required certifications (20+ specific items from your mechanical specifications)

Lighting Checklist: Lumens, CCT, CRI, mounting type, lens configuration, dimming compatibility, DLC Premium listing (12+ items from electrical specifications)

Why it matters: Checklists ensure complete consistency across different submittal reviewers. This helps systematically train junior PEs on what matters and guarantees nothing critical gets forgotten or overlooked. Share proper documentation across all team members and update regularly based on lessons learned.

Check out our free MEP submittal checklist here:

5. Adopt Construction Specific AI for Systematic Technical Review

Manual review processes don't scale effectively for large projects with 1,000+ submittals. AI can systematically check every requirement without fatigue, distraction, or knowledge gaps. Technology frees your team for coordination, problem-solving, and work requiring human judgment.

The results: 70-80% time savings and rejection rates below 5%. The technology is proven, reliable, and delivering measurable results on projects right now.

The approach isn't 'trust the AI blindly.' BuildSync provides the technical analysis; your team reviews the findings and makes final determinations. Think of it as a tireless junior PE who systematically checks every specification without getting fatigued - but you're still the engineer of record making the calls

BuildSync provides seamless integration with Procore workflows, automatically pulling submittals and specifications and generating detailed compliance reports without manual data entry or workflow disruption.

Check out our expert review of 9 best construction submittal software for a better idea of how submittal software works.

Caption: BuildSync Characteristic Technical Requirement Comparison

Why it matters: This is the only solution that actually fixes the math problem. It's not about working harder or being more diligent. It's about using technology that can handle the scale and complexity of modern submittal review. The AI handles extraction and comparison systematically; your team handles judgment, coordination, and decision-making.

Transform Your Construction Submittal Review Process

Construction submittal reviews represent one of the most time-intensive, detail-critical processes in project delivery. The traditional manual approach - extracting data from 70-page manufacturer cut sheets and cross-referencing against dense technical specifications - simply doesn't scale for modern commercial construction projects with thousands of submittals.

The industry reality: High rejection rates adding weeks to construction timelines, overwhelmed project teams drowning in backlog, and strained relationships with design teams have become normalized.

But this doesn't have to be your reality.

Construction teams across the country are adopting AI-powered submittal review to fundamentally transform this process. By automating technical extraction, specification comparison, and compliance verification through effective document management, forward-thinking teams are achieving dramatic results:

Rejection rates consistently below 5%

70-80% time savings on otherwise manual review work

Submittals processed in hours instead of days or weeks

PEs freed up for coordination, problem-solving, constructability reviews, and valuable work

Systematic coverage of every specification requirement without exception

Consistent quality regardless of volume, reviewer experience, or time pressure

Your Next Step

If you're using Procore: See how BuildSync integrates seamlessly into your existing workflow in a 30-minute demo. Zero training required for your team - BuildSync becomes an actor in your submittal workflow and delivers detailed compliance reports without disrupting anything you're currently doing.

If rejection rates are killing your schedule: Stop letting submittal rejections add weeks to your timeline. See how BuildSync catches non-compliance before it reaches the design team - with specific examples from projects like yours.

If your PEs are drowning in submittals: Try BuildSync on your three most complex submittals - the ones that would normally take 6-8 hours to review manually. See the comprehensive analysis BuildSync delivers in hours, not days.

No long sales pitch. Just see it working on your actual submittals.

Frequently Asked Questions About Construction Submittal Reviews

Related reads for you

Discover more articles that align with your interests and keep exploring.