Construction Technology & Innovation

/

Dec 31, 2025

Why Submittals Get Rejected: Top Causes & Solutions (2026)

Learn the 7 main reasons construction submittals get rejected and proven strategies to fix them. Reduce your rejection rate and avoid costly resubmittals and delays.

Another submittal kicked back from the design team. Two weeks lost. Again.

If you're a project manager in commercial construction, this scenario is painfully familiar. The industry average tells the story: 30-40% of construction submittals get rejected on first submission.

That's not a typo. Nearly four out of every ten submittals you send to the design team come back marked "Revise and Resubmit" or worse, "Rejected."

Understanding why submittals get rejected is the first step toward fixing the problem. Each rejection doesn't just add 2-3 weeks to your timeline - it creates a ripple effect that impacts the construction schedule, relationships with the owner and design team, and your bottom line.

BuildSync's survey of over 6,000 construction professionals revealed that each rejected submittal costs an average of $805 when you account for labor hours, coordination time, and downstream schedule impacts.

This isn't sustainable. But here's the reality: most companies think they have a "people problem" when they actually have a "process problem." The manual submittal review process simply cannot scale to deliver the technical depth required across hundreds or thousands of project submittals per project.

This article reveals the seven root causes of why submittals get rejected and provides a practical framework for reducing your rejection rate without adding headcount or changing your existing submittal workflow.

What Are Submittals in Construction?

Construction submittals are the formal documentation packages that contractors submit for approval before materials are purchased or work begins. They demonstrate exactly how the contractor plans to fulfill the project requirements specified in the contract documents.

A submittal package typically includes product data sheets (cut sheets), shop drawings showing fabrication details with installation instructions, material samples, test reports, and certifications. The construction submittal review process serves as a critical quality control checkpoint - ensuring that what gets installed on site matches the design intent.

The submittal workflow is straightforward in theory: the subcontractor prepares the submittal package, sends it to the general contractor for coordination review, the GC forwards it to the design team (architect and engineers), and the design team reviews it against the project specifications. If everything complies, the submittal receives a "No Exceptions Taken" stamp and work can proceed. If not, it comes back rejected.

But here's where theory meets reality.

The stakes are high for successful projects. Approve the wrong product, and you face costly replacements down the line. Reject too many submittals, and you create construction delays that cascade across multiple trades.

How the Construction Submittal Review Process Actually Works (And Why It Breaks Down)

Most people outside the construction industry don't realize the sheer technical complexity involved in the submittal review process. Let's walk through what actually happens when a project engineer sits down to review an air handling unit submittal.

The submittal documents might total 60-80 pages. The project specifications for that division could be another 30-50 pages. The PE needs to extract every critical data point from the submittal - refrigerant type, motor horsepower, fan RPM, coil configurations, filter ratings, control sequences, warranty terms, spare parts, certifications - and verify each one against the specifications.

For a complex piece of equipment, that's easily 50+ individual technical characteristics to check. And they all need to be verified against the correct specification sections, which might reference multiple divisions and cross-reference other sections in the contract documents.

Now multiply that by hundreds of construction submittals per project. On a $50M commercial building, you might process 2,000+ submittals. Each construction submittal requires the same level of thorough review and quality assurance.

Submittal Complexity | Equipment Examples | Typical Page | Average Manual | Number of Data Points to Verify |

Simple | Light fixtures, door hardware, paint samples | 5-15 pages | 30-60 minutes | 10-15 characteristics |

Medium | VAV boxes, pumps, exhaust fans, electrical panels | 20-40 pages | 2-4 hours | 20-35 characteristics |

High | AHUs, chillers, boilers, elevators, curtain wall systems | 60-100+ pages | 8-20 hours | 50+ characteristics |

The Expertise Challenge

The review and approval process requires understanding mechanical systems, electrical requirements, material specifications, code compliance, environmental conditions, and coordination across trades. Junior project engineers often don't have this depth of knowledge yet. Senior project managers rarely have the time to do this level of detailed review themselves.

The Volume Problem

Large construction projects need speed AND accuracy, but the manual submittal review process can't deliver both. You can spend weeks doing thorough reviews, or you can rush through them and miss critical details. Either way, the rejection rate stays high.

This is why the construction submittal process breaks down. It's not that people aren't trying - it's that the manual process cannot scale to match the technical depth required across the volume of submittals on modern construction projects.

Top 7 Reasons Why Submittals Get Rejected

Let's break down the specific reasons why submittals get rejected in the review process. Understanding these patterns is the first step toward managing submittals more effectively.

Reason 1: Incorrect Product Specifications

Incorrect product specifications are the most common rejection cause. The submitted product doesn't match what's specified - wrong manufacturer, wrong model, wrong technical characteristics.

Real Example: Submittal shows a rooftop unit with R-454B refrigerant. Project specifications call for R-410A refrigerant. The product engineer catches this during the submittal review, marks it as a fail, and the submittal comes back rejected.

Why it happens: The PE reviewing the 70-page submittal doesn't catch the discrepancy buried on page 47. Or the subcontractor uses generic product data that doesn't exactly match project requirements. There could also be a last-minute value engineering attempt that wasn't properly coordinated through the submittal process.

Impact: If this gets approved by mistake, you discover the issue when the equipment arrives on site - and now you're facing a six-figure replacement cost and a potential legal dispute over who pays for it. The contractor remains responsible for compliance even if the submittal was approved.

Reason 2: Missing Technical Data Points

Critical specifications required by the project aren't included in the submittal package. The design team has no way to verify compliance because the performance data simply isn't there.

Real Example: Glazing submittal includes manufacturer information and glass type, but omits the light transmittance value. Specifications require a minimum 42% visible light transmittance for the space. Without this technical data, the submittal cannot be approved.

Why it happens: Subcontractors often use the manufacturer's standard product data sheets, which don't always address every project-specific requirement. The manufacturer's cut sheet shows what they consider important - not necessarily what your submittal requirements demand.

Impact: Design team marks it "Revise and Resubmit" and sends it back. Minimum two-week delay while the sub obtains the missing performance data from the manufacturer, creating submittal delays.

Reason 3: Substitutions Without Proper Documentation

The submitted product differs from the specified manufacturer or model, but there's no approved substitution request with proper documentation.

Real Example: Specifications call for glazing from Viracon, Guardian Industries, OldCastle Building Envelope, or Pilkington North America. Submittal proposes TechnoGlass product - a manufacturer not on the approved list. No substitution request was submitted prior.

Why it happens: Subcontractors try to value engineer without following the proper substitution process outlined in Division 01 of the specifications. Or they assume "equivalent" products are acceptable without final approval.

Impact: Automatic rejection. The sub now needs to either submit an approved manufacturer or go through the formal substitution request process, which can add 3-4 weeks to the submittal schedule while the design team evaluates whether the proposed product is truly equivalent.

Reason 4: Incomplete Product Data

The submittal provides partial information but doesn't address all submittal requirements.

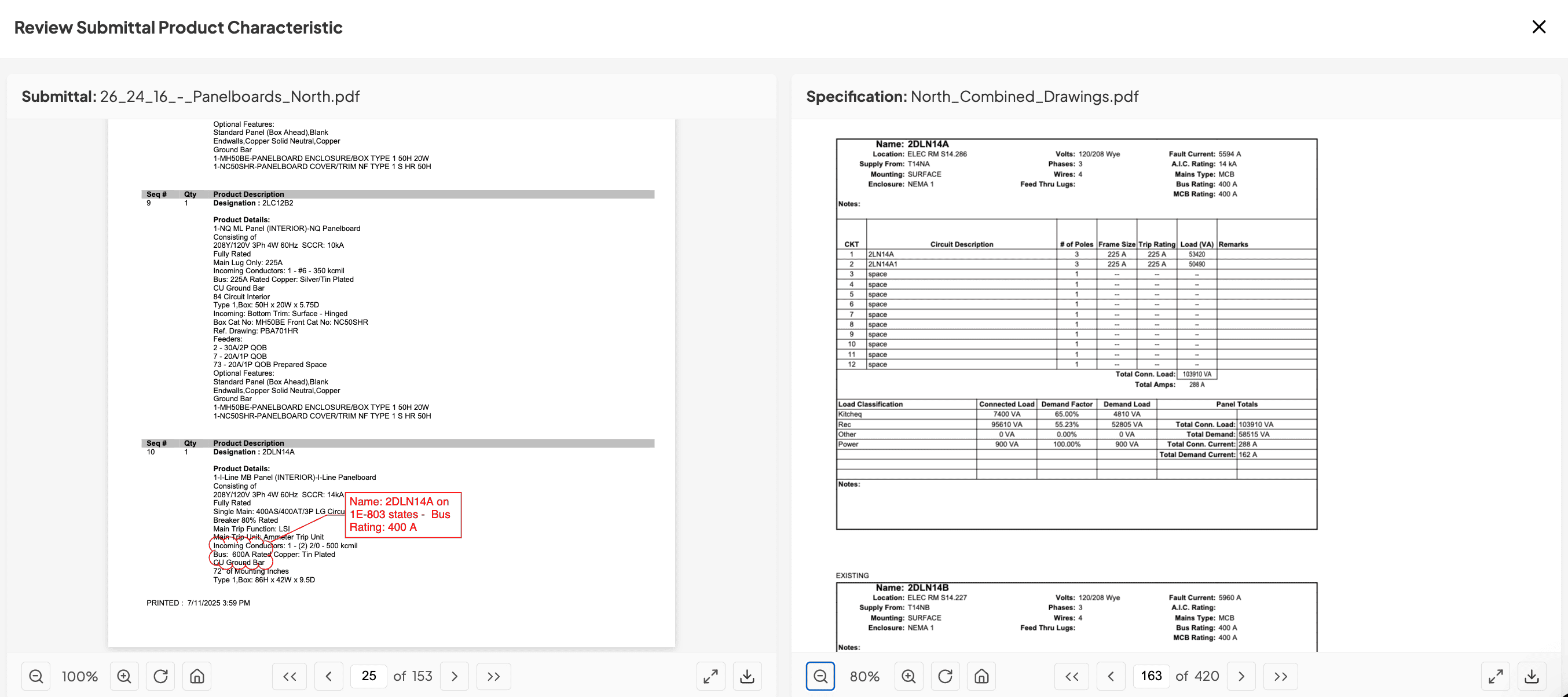

Real Example: Equipment submittal includes performance criteria but doesn't specify warranty terms. Specifications require 10 years from the date of substantial completion. Without this being clearly stated, BuildSync marks it as "Unknown" status, which means it can't be approved until clarified.

Why it happens: Vendor catalogs include standard warranty information (maybe "2-year parts warranty") but don't address project-specific requirements like warranty duration calculated from the substantial completion date rather than the shipment date.

Impact: Creates an "Unknown" status that stalls the approval process. The project manager or PE must now contact the manufacturer, get written confirmation of the warranty terms, and potentially resubmit. This adds coordination time and delays approval.

Tom Port, the co-founder of BuildSync, says:

“We often notice that submittals don’t fail because something is wrong; they fail because something is missing. Manual reviews are good at spotting red flags, but weak at systematically identifying gaps. Those ‘unknowns’ are what trigger late rejections and unnecessary back-and-forth. I often tell our customers that there are golden insights in what BuildSync will flag as unknown.”

Reason 5: Incorrect Coatings or Finishes

Wrong material finishes, protective coatings, or surface treatments that don't meet environmental or performance requirements.

Real Example: HVAC equipment submittal shows standard coil coating. Specifications require a corrosion-resistant coating for a salt air/salt fog environment because the building is in a coastal location. The standard coating will fail prematurely in that environment.

Why it happens: The PE doesn't recognize the environmental requirement buried in Section 23 or doesn't connect it to the specific equipment being reviewed during the review process. Or the subcontractor provides their standard product configuration without customizing it for the project conditions.

Impact: If approved incorrectly, the equipment will corrode faster than expected, leading to premature failure and warranty disputes. If caught during the submittal review process, it's rejected and sent back for correction. The contractor remains responsible for meeting all project requirements and contractual obligations.

Reason 6: Missing Certifications or Testing

Required certifications, testing documentation, or compliance reports aren't provided with the submittal documents as technical submittals.

Real Example: Structural steel submittal with shop drawings lacks required mill test reports or seismic certifications. Fire-rated assembly submittal is missing UL listing documentation. Electrical equipment submittal without the required testing agency approval.

Why it happens: The sub doesn't realize specific certifications are required because they're referenced in multiple spec sections or buried in technical requirements. Or the manufacturer doesn't routinely provide certain certifications unless specifically requested.

Impact: Cannot proceed without required certifications. In some cases, installed work may need to be removed and replaced if the certification issue is discovered after installation, creating significant submittal delays and project schedule impacts.

Reason 7: Accessories and Extra Materials Not Addressed

Required spare parts, filters, belts, and other accessories specified in the project aren't listed on the submittal package.

Real Example: AHU specifications require spare fan belts and filters to be provided as part of the closeout. The submittal focuses on the main equipment but doesn't address these accessories at all.

Why it happens: Everyone focuses on the primary equipment specifications and overlooks the accessory requirements. BuildSync's analysis shows these requirements are often in separate specification sections or buried in Part 3 (Execution) rather than Part 2 (Products) where people look during the construction submittal review process.

Impact: Discovered during project completion when the project owner asks for attic stock and spare parts. Now you're holding retention while scrambling to order and deliver items that should have been included in the original scope. This delays final approval and creates friction in GC-owner relationships.

The Ripple Effect of Submittal Rejections

Let's talk about what those submittal rejections actually cost - because it's more than just an annoyance to the project team.

Timeline Impact: The 2-3 Week Penalty (Minimum)

When spec conflicts arise, many teams submit RFIs labeled as submittals or vice versa - understanding the submittal vs RFI distinction prevents routing errors that add weeks to your approval timeline.

Each submittal rejection triggers a revision and adds a minimum of 2-3 weeks to your project schedule. Here's the math:

Step in the Rejection Cycle | Responsible Party | Time Required | Cumulative Days (Min-Max) |

1. Receive rejection notification | Subcontractor | Same day | 0 |

2. Coordinate with the manufacturer to address issues | Subcontractor | 3-5 days | 3-5 |

3. Manufacturer provides revised documentation | Manufacturer | 3-7 days | 6-12 |

4. Sub resubmits to GC | Subcontractor | 1-2 days | 7-14 |

5. GC re-reviews submittal | General Contractor | 2-3 days | 9-17 |

6. GC resubmits to the design team | General Contractor | Same day | 9-17 |

7. Design team re-reviews | Architect/Engineer | 7-14 days (per contract) | 16-31 |

TOTAL DELAY PER REJECTION | Multiple parties | 16-31 days | 2.3-4.4 weeks |

Note: This assumes the resubmittal is correct the second time. Multiple rejection cycles compound these delays exponentially.

Total: 16-31 days, or roughly 2-4 weeks. And that's assuming the resubmittal is correct the second time. For critical path items, this cascades across the entire project schedule. A rejected structural steel submittal with shop drawings doesn't just delay steel erection - it delays mechanical rough-in, which delays drywall, which delays finishes, which delays occupancy.

Cost Impact: $805 Per Rejection (On Average)

BuildSync's research shows the average submittal rejection costs $805 when you account for:

Direct Labor Costs:

PE time preparing resubmittal: 4-8 hours

Project manager time coordinating with sub and manufacturer: 2-4 hours

Admin time for submittal tracking and resubmitting: 1-2 hours

Design team review time (again): 2-6 hours

Indirect Costs:

Schedule delay impact (varies by criticality)

Coordination meetings to address the issue

Expediting fees if timeline is compressed

Potential overtime or acceleration costs

Do the math on your projects:

A typical project processing 2,000 submittals at 35% rejection rate:

700 rejections × $805 = $563,500 in rejection costs annually

Even a modest rejection rate adds up fast. At 20% rejection:

400 rejections × $805 = $322,000 in rejection costs

Relationship Impact: The Hidden Cost

Beyond dollars and days, there's the relationship strain:

GC-Subcontractor Relationships: Constant submittal rejections create friction. Subs feel like GCs aren't reviewing properly before sending to design. GCs feel like subs aren't doing their homework before submitting.

GC-Design Team Relationships: Architects and engineers get frustrated reviewing poorly-prepared submittals. When 40% of what you send them comes back rejected, they start questioning your quality control capabilities. Your reputation suffers.

Impact on Future Work: The design team remembers general contractors who consistently submit high-quality, compliant submittals. They also remember those who don't. This affects your ability to win future work with that design team or building owner.

Opportunity Cost: What Your Team Isn't Doing

Every hour a project manager or PE spends on resubmittals is an hour NOT spent on:

RFI coordination and resolution

Project schedule management and recovery

Quality control and field inspections

Proactive problem-solving

Building owner and stakeholder relationships

Mentoring junior team members

The opportunity cost of submittal rejections extends beyond the immediate project impacts. You're trading high-value project management activities for low-value administrative rework.

Want to see how much your submittal rejection rate is actually costing your projects?

Request a BuildSync demo to analyze your specific project data and discover where you're losing time and money in the construction submittal review process.

How to Manage Submittal Rejections

Now let's talk solutions. Not generic "try harder" advice - practical approaches based on which bucket of problems you're in.

The Three Buckets: Which One Are You In?

Before we dive into solutions, you need to identify your specific situation. BuildSync's customer data shows three distinct patterns:

Factor | Bucket 1: High Rejection | Bucket 2: Time Drain | Bucket 3: Both Problems |

Companies Affected | 10% | 10% | 80% |

Current Rejection Rate | 30-40% | 10-15% | 20-30% |

Time Spent on Reviews | Moderate | Excessive (20+ hrs/week) | Excessive |

Primary Pain Point | Schedule delays from rejections | Team capacity exhausted | Quality & efficiency both suffering |

Root Cause | Inadequate technical review depth | Manual process can't scale | Junior PEs without expertise; poor/no reviews |

What You Need | Better quality control before submission | Automation to free up team time | Comprehensive solution for both |

Recommended Solution | Tier 3 (AI-powered deep analysis) | Tier 3 (Automation + quality) | Tier 3 (Systematic AI review) |

Expected Outcome | 35% → 5% rejection rate | 70-80% time savings | Both metrics improved |

Most companies fall into Bucket 3 - you're getting too many submittal rejections AND spending too much time on the review process. The manual approach can't scale to deliver both accuracy and speed.

Tier 1: Immediate Actions (Any Company Can Implement Today)

Start with these practices regardless of your current construction submittal process:

Create Pre-Submission Checklists: Develop standardized checklists for common equipment types (AHUs, RTUs, lighting packages, VAV boxes, etc.). Every submittal should be checked against the list before submission to the general contractor or design team.

Include items like:

All manufacturer product data included?

All required certifications attached?

Spare parts and accessories addressed?

Warranty terms clearly stated?

Correct product model matches specification?

Establish Submittal Coordination Meetings: Hold kickoff project meetings with major trades before first submittals. Review submittal requirements, clarify any questions, and establish a submittal schedule with realistic timelines.

Mandatory Spec Cross-Reference: Require PEs to document which spec section(s) they reviewed for each characteristic. This forces a systematic review rather than spot-checking and helps verify compliance across the entire process.

Reality Check: These help, but they don't solve the fundamental scale problem. A checklist doesn't extract 50+ data points from a complex submittal and verify each one against hundreds of pages of specifications in the construction documents.

Tier 2: Process Improvements (Medium-Term Implementation)

Standardize Submittal Package Requirements: Create submittal requirement templates for each division. Clearly communicate to subs exactly what needs to be included. Reduce ambiguity about what "complete" means.

Invest in PE Training: Formal training programs on technical review for different systems. Help junior project engineers understand what to look for and where common issues hide in specifications.

Earlier Design Team Engagement: Loop in the design team during preconstruction for complex projects. Get their input on critical submittal requirements before submittals are formally submitted.

BIM Coordination Integration: Use building information modeling to catch coordination clashes before submittal submission. Identify conflicts between mechanical, electrical, plumbing, and structural systems early in the construction submittal process.

Reality Check: These process improvements work, but they require significant time investment. You're still fundamentally limited by the manual review process bottleneck - checking each characteristic against specifications one by one.

Tier 3: Technology-Enabled Solutions (The Game Changer)

This is where you move from incremental improvement to transformational change.

AI-powered submittal review fundamentally changes the equation by automating the extraction and verification of technical data points. Here's how it works:

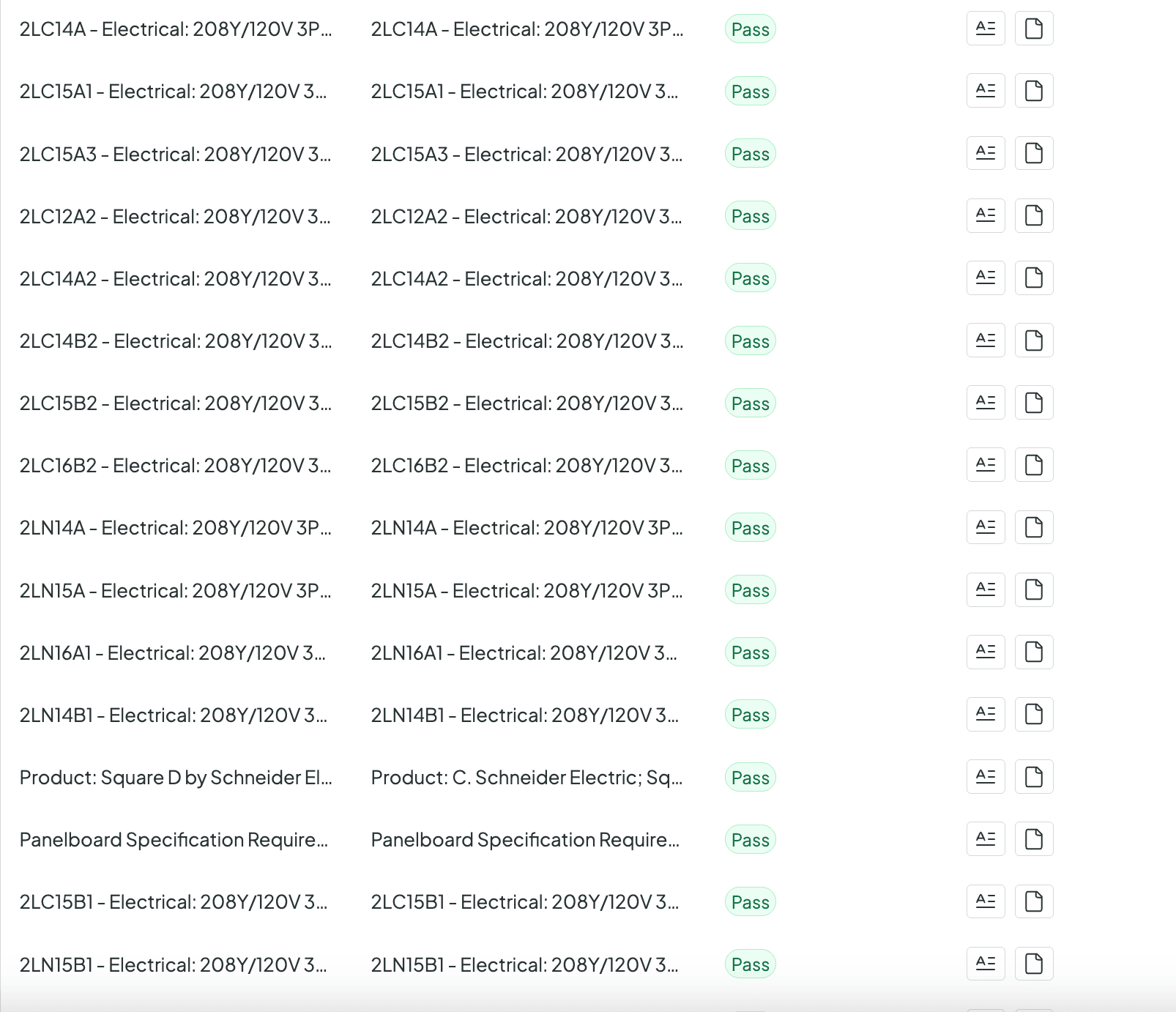

Deep Technical Analysis: The construction technology extracts every characteristic from the submittal - refrigerant type, motor specs, coil configuration, warranty terms, certifications, spare parts, everything. Then it compares each characteristic against the project specifications systematically.

For that 60-page AHU submittal? BuildSync extracts 50+ individual technical characteristics and checks each one against specs in hours instead of days, reducing submittal turnaround time dramatically.

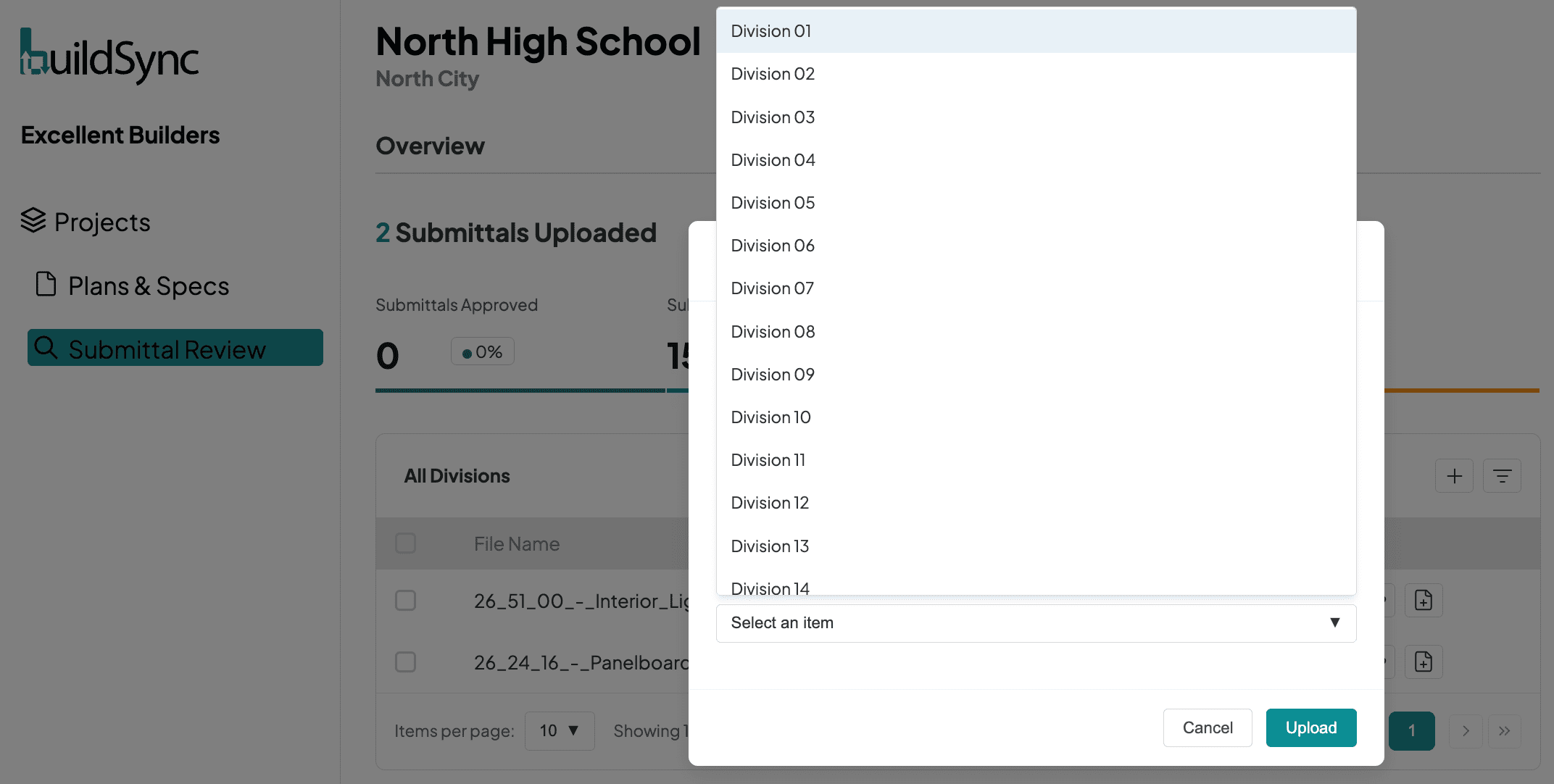

Zero Friction Integration: The key to adoption is seamless integration with existing submittal workflows. BuildSync integrates directly with Procore - operating as an actor within your submittal workflow. Subs submit to Procore just like they always have. BuildSync performs the technical review in the background. The general contractor receives the analyzed submittal with a detailed pass/fail/unknown breakdown for each characteristic.

Setup takes minutes. No workflow changes. No training required for subs. The project team stays on the same page.

The Results:

Rejection rate: From the industry average of 35% down to 5%

Time savings: 70-80% of hours otherwise spent on manual review

Review speed: Hours instead of days or weeks

Technical depth: Every data point checked, not just the obvious ones

The Trust But Verify Principle:

Construction technology doesn't replace human judgment - it augments it. BuildSync shows you exactly where each characteristic was pulled from in both the submittal and specifications. You verify the AI's findings and make the final call. But now you're reviewing analyzed data instead of manually extracting it from 70-page submittal documents.

When asked about the breakthrough moment companies have during the manual submittal review, Tom says:

“The lightbulb moment usually happens during a pilot. That’s when teams see issues flagged that even their most experienced PE or PMs may have missed. This is never because they’re bad at their job, but because manual review forces them to spend hours extracting information instead of actually reviewing it. Once they see how much time is wasted on that extraction work, BuildSync's value becomes clear pretty quickly.”

The construction industry has been slow to adopt AI, often for good reasons - skepticism about whether technology can handle the technical complexity. But the submittal review process is one of the clearest use cases.

The requirements are documented (specifications), the inputs are structured (product data), and the comparison is systematic (verify compliance against each requirement).

This isn't theoretical. Companies processing thousands of submittals annually are seeing 5% rejection rates where they used to see 35%. The math works for successful projects.

Best Practices for First-Pass Submittal Approval Process

Whether you implement submittal software or stick with manual processes, these tactical practices improve first-pass approval rates and help with managing submittals effectively:

For Subcontractors:

Start Early: Begin submittal preparation during preconstruction, not when submittals are due on the submittal schedule. Give yourself time to address issues before the formal submission deadline.

Use Manufacturer Reps: Leverage manufacturer representatives to verify compliance before submission. They know their products and can quickly identify if shop drawings or product data don't meet project requirements.

Create Detailed Submittal Log: Track all submittal requirements for your scope in a submittal register. Cross-reference each submittal item against specification sections. Don't rely on memory or assumptions about what submittals represent.

Address Accessories Upfront: Don't focus only on primary equipment. Systematically review specifications for required spare parts, filters, belts, special tools, and training requirements. Include everything in the submittal package as physical examples when possible.

Highlight Substitutions Clearly: If proposing a different product than specified, make it obvious. Don't bury it hoping it gets approved. Follow the proper substitution request process documented in Division 01 and use clear submittal language.

For General Contractors:

Set Clear Expectations in Subcontracts: Define submittal requirements explicitly in subcontractor agreements. Specify what "complete and compliant" means. Reference spec sections that apply to each trade's scope. Ensure contractor reviews are thorough.

Conduct Submittal Kickoff Meetings: Hold dedicated project meetings with each major trade to review their submittal requirements. Clarify expectations, answer questions, establish realistic timelines for tracking submittals.

Create Review Checklists by Equipment Type: Develop standardized checklists for common submittals (RTUs, AHUs, lighting, VAV boxes, shop drawings for custom work, etc.). This ensures consistent quality assurance across different PEs and construction projects. Organizing your submittals consistently from the start prevents many common rejection causes - use our construction submittal template to ensure you capture all required fields including certifications, warranties, and technical specifications.

Allow Adequate Review Time: Don't compress the review process just to meet the construction schedule. Rushed reviews miss details. If the schedule doesn't allow proper review time, address the schedule - not the review depth. Treat this as one of the common submittal challenges.

Provide Detailed Rejection Feedback: When rejecting a submittal, be specific about what's wrong and what needs to change. "Revise and resubmit" with no explanation wastes everyone's time. Point to the exact spec requirements that aren't met and reference relevant documents.

For Everyone:

Document Everything: Every decision, every clarification, every approval. Create an audit trail. When disputes arise months later, proper documentation is your protection and ensures the contractor's submittals are properly tracked.

Communicate Proactively: Don't wait for problems to surface in the design team review. If you spot a potential issue, raise it immediately. Early coordination prevents formal rejections and keeps other submittals moving forward.

Learn from Patterns: Track rejection reasons across project data. If you're consistently getting dinged for missing certifications or incomplete warranty information, that's a systematic problem to fix - not a one-off issue affecting project size.

Leverage Technology Thoughtfully: Use tools that augment human judgment, not replace it. The goal is to free up your team for high-value decision-making by automating the tedious data extraction and comparison work in shop drawings and product data.

According to BuildSync’s comprehensive submittal guide, effective submittal management requires clear communication channels and collaborative platforms that give all stakeholders visibility into submittal progress and requirements.

The "Trust But Verify" principle applies regardless of whether you're using manual review or AI-powered analysis. Always verify the source documents. Understand where in the specifications each requirement comes from. Build institutional knowledge about common submittal challenges for your project types and ensure detailed plans are followed.

Ready to reduce your submittal rejection rate from 35% to 5%?

See BuildSync in action with a free pilot on your actual project submittals. No workflow changes required - integrate with Procore in minutes and discover what systematic technical analysis can do for your construction projects.

Conclusion: Stop Accepting 35% as Inevitable

Submittal rejections aren't an unavoidable cost of doing business in construction. They're a systematic problem with systematic solutions.

The industry's 30-40% rejection rate exists because the manual submittal review process cannot scale to deliver the technical depth required across hundreds or thousands of submittals per project. You're forced to choose between thoroughness and speed - and either choice results in high rejection rates, excessive time drain, or both.

Here's what we know from analyzing the submittal process across thousands of construction projects:

The problem is clear: Seven primary rejection causes account for most issues - incorrect product specs, missing data, improper substitutions, incomplete information, wrong coatings, missing certifications, and overlooked accessories. Each rejection costs $805 on average and adds 2-3 weeks to your project schedule.

The impact is real: At 35% rejection rate, a project processing 2,000 submittals loses over $560,000 annually to rejection cycles. The timeline delays cascade across trades. The relationship strain with the design team and owners affects your reputation and future work.

The solution exists: Companies are reducing rejection rates from 35% to 5% by implementing systematic review processes - extracting every data point from submittal documents and verifying each one against specifications. Technology now delivers this level of analysis in hours instead of days, with zero-friction integration into existing submittal workflows.

The question isn't whether AI-powered submittal review works - the data proves it does. The question is how quickly you implement it before your competitors do and start winning construction projects based on faster schedules, better relationships with design teams, and proven submittal quality.

Stop accepting 35% rejection rates as inevitable.

Request a BuildSync demo and see how AI-powered submittal review transforms your construction submittal process. Zero friction Procore integration, setup in minutes, and proven results on your actual project submittals. Run a pilot with your five most complex submittals and see the difference systematic technical analysis makes.

Frequently Asked Questions

Why do submittals get rejected?

Submittals get rejected primarily because they fail to meet project specifications in one or more critical areas. This includes incorrect product specifications, missing technical data, improper substitutions, incomplete product information, incorrect coatings or finishes, missing certifications, or unaddressed accessories. Here's the thing though: the root cause is usually inadequate technical review before submission, not intentional non-compliance. The real challenge is scale. Manual review of a complex submittal requires checking 50+ individual data points against hundreds of pages of construction documents. Even experienced project engineers miss details when they're processing high volumes in the construction submittal process. This is exactly why the industry maintains that persistent 30-40% rejection rate we all know too well.

What are the most common reasons for submittal rejection?

How do I avoid submittal rejection?

What happens when a submittal is rejected?

Related reads for you

Discover more articles that align with your interests and keep exploring.